Your Custom Text Here

Fibre Farming for Resilience and Success

This is a lecture Anna presented to the Southeast New England Fibreshed. The focus was on how to build resilience in to our fibre farming businesses.

Good Wool: A deep dive into the science and strategy of growing good wool

Enjoy this lecture - informational slides are below.

Good Wool Lecture password is ‘goodwool’

Sheep School: Starting Your Own Flock

Have you always wanted to raise sheep? Are you ready to grow your own wool? Or expand your existing farming plans? This is an online workshop that will provide information and recommendations for starting your own flock of Sheep. The workshop will touch on the following topics:

Breed consideration

Infrastructure for Sheep

Feeding & Breeding

Finances and Funding

Marketing

Q&A with a fibre farmer

Download the Manual

You can download a copy of the manual here.

Breed Specific Knitting

Each breed of sheep produces a distinct type of wool for knitting and crochet. Understanding the qualities and characteristics of these breeds will inform and accentuate your knitting. Texture, colourwork, cables and drape are all affected by the unique wool breeds.

This workshop will explore the aspects and features of sheeps wool and provide an overview of some accessible single-breed wools and the variety they can offer to your knitting. We will dive into the history and tradition of these unique sheep breeds and their wool.

Breed Specific manual can be downloaded here.

Course Manual

Breed Specific manual can be downloaded here.

You can find the full text of the manual after the video.

This manual is Copyright 2024 Anna Hunter, Long Way Homestead

Course Video

Course Manual Content

Breed Specific Knitting

“All wool, whatever its characteristics, can be satisfactorily used for one purpose or another, but none can be satisfactorily used for every purpose” - In Sheep's Clothing

Why Breed Specific Matters

It helps preserve specific breeds, especially those that are rare and at risk.

Helps us learn more about wool and its characteristics so we can capitalize on the unique characteristics of that fibre, and inform our fibre arts.

Supports small farmers, small mills and small businesses.

Many ask how long until you recuperate your costs, or what are sales like. I can only share our experience. We applied for and received a grant from our Provincial government. If you can find similar programs for agricultural processors it will help cover some of the early costs.

Here is a sample of our first two years of sales. We had very low overhead costs as we already had significant waste wool and didn't need to purchase much wool than the original $500.

I believe that for us in our zone 3 growing season - the pellets will be a seasonal product only. So we will need our sales to be heavy between April and August.

Troubleshooting

Why are my pellets crumbling and not holding shape? - moisture is essential for pellets staying together. You can add water via a spray bottle to the hopper while making your pellets. It is more crucial to add moisture if you are pelleting in a colder/dry climate in winter.

How many pounds of pellets can I produce in an hour? - Without a chopper you should be able to constantly feed the hopper with wool and produce around 20-30lbs an hour (this includes some time for cleaning out the wrapping wool.

How do I use wool pellets in my garden? - You can directly apply wool when planting seeds - space your seeds out in your row and then sprinkle the wool pellets alongside your seeds. Cover up seeds and wool with soil. 1kg of pellets can be applied to approximately 20-25 square feet of garden.

Pre mix for pots – mix 1/2 cup pellets with 4 litres of soil and add to your pots. Plants that are already potted - sprinkle the wool pellets on the top of the plants and push them down. Or leave them on top for pest repellent (they will not break down as quickly on top of the soil).

How much garden will one bag of wool pellets cover? - 1kg of pellets can be applied to approximately 25 square feet of garden.

How long will wool pellets last in my garden? - When pellets are mixed with the soil they will start breaking down within 3 months. When used as a mulch it will take closer to 12 months to start breaking down. The nutrients in the pellets will release gradually and can last up to a year.

Will there be any transfer of weed seeds from the sheep fleece? - Definitely NOT. The heat used during the process of pelleting will destroy any seeds in the wool. It gets heated up to approximately 200 degrees farenheit

All information copyright Anna Hunter, Long Way Homestead 2024

History of Wool Textile Production in Canada 1750 - 1980

Lecture Presentation

Did you know that Canada used to produce 90% of all the textiles we consumed? Now we produce less than 5% and most of the raw materials are sourced outside of Canada. This lecture will look at the social, political and environmental factors that changed our textile industry and what opportunities exist to revitalize the Canadian wool industry from a manufacturing and industry perspective.

Course Manual

There is no course manual for this lecture.

Course Video

Course Lecture Citations

McCullough, A.B. The Primary Textile Industry in Canada History and Heritage. Minister of Suppy and Services Canada (1992)

Tremblay, Robert. The Textile Industry in Canada from 1870 to Present Day. Canada Science and Technology Museum, Ottawa (2007)

All information copyright Anna Hunter, Long Way Homestead 2024

Wool Pellets - Opportunitites and Considerations

As more innovative ideas emerge for dealing with our abundance of unused or ‘waste’ wool in N. America, many are looking at adding wool pelleting operations to their existing wool based business.

This 1.5 hr workshop will look at our journey and considerations for adding a wool pelleting operation to our business. The workshop will look at:

equipment and infrastructure needs

research on wool in the soil

sourcing waste wool

packaging

marketing

finances

Q & A

Course Manual

Wool Pellet Opportunities and Considerations Manual

You can find the full text of the manual after the video.

This manual is Copyright 2024 Anna Hunter, Long Way Homestead

Course Video

Course Manual Content

Introduction

As more innovative ideas emerge for dealing with our abundance of unused or ‘waste’ wool in N. America, many are looking at adding wool pelleting operations to their existing wool based business.

We initially started looking into wool pelleting as a way to achieve zero waste goals for our wool processing mills. Very quickly it become clear that wool pellets are an opportunity to bridge the gap between our lack of infrastructure for processing wool in Canada and the abundance of wool that is being under-utilized.

We believe that pelletizing wool can be an effective tool in regions across N. America to begin adding value to wool, returning nutrients to the soil and compensating farmers for their work. We hope this workshop and these resources help you in your process and business planning for introducing a pellet machine to your existing or new operation. We hope this manual will help you get started on your own journey and please reach out if you have more questions! (info@longwayhomestead.com)

Equipment & Infrastructure

Pellet machines are not a new invention, many have been pelleting wood, alfalfa, feed, straw, hops, paper and more. The process of pelleting wool uses the same machinery and process as these other common forms of pelleting. The one challenge to pelletizing wool is the fibrous nature and long staple length of wool. Thankfully, there are some engineers out there who have already figured out how to accommodate this challenge.

Most pelleting systems include a pelleter machine – using a powerful motor to push large metal rollers over a die plate that forces the wool down into the holes and out the chute as a small pellet. Due to the fibrous nature of wool, many companies have utilized a chopper to cut the wool up into smaller pieces to make the pelleting process more expedient and less chances for wrapping of wool around the rollers. You do not need a chopper to pelletize, but it will increase production and reduce the maintenance and cleaning on the pelleting machine.

The machinery itself is not specialized (with the exception of the die plates) many have experimented with other feed and/or wood pelleters for their wool pelleting needs. There are a few companies that have set themselves apart in terms of manufacturing specifically wool pellet machinery.

Wild Valley – USA

They patented wool pellets a few years ago and have made a name for themselves as all things 'wool pelleting' at one point they sold pelleting/chopping equipment, but required exclusivity arrangements with buyers and retained a portion of sales (this may not be the case any more). In 2018 their set up was around $35,000 USD

https://www.wildvalleyfarms.com/wool-pellets.html

In terms of other infrastructure and Equipment needs:

Elf Pellet Mills – EU, USA, CANADA

The Elf pellet mill comes with a chopper and a pelleter. They claim that about 100lbs of wool can be pelleted per hour. The equipment and customer service of the company is excellent. The challenges are in the supply chain (equipment and parts coming from Europe) and also the phase 3 power. The machines will not run on phase 1 power like most of the USA & Canada have. If you have a way to convert the power on site, then the equipment is an excellent choice. In late 2021 it was approximately $30,000CAD

https://elfpelletmills.com/wool-pellets/

Buskirk Engineering – USA

Buskirk is who I purchased my pelleting machine from. They are an engineering firm in Indiana, USA. They did not start out intending to work with wool, but have found a bit of niche in making pelleters for wool. They have finished the prototype for a wool chopper and now they sell both. They also have a PTO pelleter option. The pellet mill is $7,800.00 + shipping. The wool shredder is $6,342.00 + shipping. https://buskirkeng.com/

Electricity – your needs will depend on the machine you purchase. We had to hire an electrician to install our Buskirk machine. You will need to wire the mill - 50A breaker on the 220V single phase power for the PM805 unit (this is what we operate from Buskirk)

Space – I recommend a well ventilated space. The machine creates quite a bit of atmospheric dust, we have found that having air flow is important while pelleting, and the space will generally accumulate fibre and dust after the machine has been running. We also recommend the operator wears a dusk mask. Space for cooling pellets is also critical.

Consumables – We use a few buckets and totes for collecting pellets, sorting raw wool and waste from cleaning out the pelleter. A quality hook for cleaning out wool from the pelleter (if you do not have a chopper) and a good scoop for filling bags and sorting pellets. Quality scale for measuring/weighing out your pellets.

Cleaning & Maintenance – without a chopper we spend 10-15 minutes cleaning out the pelleter after every hour ofuse. You will need to grease the bearings and rollers every 40-60hrs.

Wool in the Soil

There are many benefits of using wool pellets in our soil:

increased aeration

increased water holding capacity

slow release nitrogen and other nutrients

decrease in pests like slugs

These are the basics of what wool pellets can do, but understanding the deeper use and effect will be important to speak with confidence to your customers.

There has been a good amount of research conducted by other businesses, colleges and research centres about the benefits of wool pellets in the soil. Many of these studies are published online and easily available:

https://shelburnefarms.org/blog/experimenting-with-wool-as-a-nitrogen-source-for-farming

https://www.uvm.edu/sites/default/files/The-Center-for-Sustainable-Agriculture/wool%20pellet%20info/wool_handout_feb22.pdf

https://www.wildvalleyfarms.com/why-wool.html

https://projects.sare.org/wp-content/uploads/agronomy-12-01210-v2.pdf

Most people have not heard of wool pellets, and so educating the consumer will be important for both marketing the product, but also transitioning from synthetic or other fertilizers to wool.

It will be important to continue studying wool pellets and to observe any positive or negative long-term effects from using wool pellets in the soil.

Sourcing Waste Wool

Many have been drawn to the idea of pelleting because of the excess of wool, or waste wool in our communities. Pelletizing wool is a more affordable option than scouring and processing it into textiles – so it works as an immediate response to the challenges of our wool industries. In our experience this is what works best for pelletizing.

Any wool will work if you have a chopper. If you do not, then you will want to ensure that the staple length is not longer than 5-6”. If it is, the potential for wrapping around the rollers is higher and you will have to spend more time cleaning the machine.

Bellies & necks are simple and easy, and don't generally require any extra prep (just make sure there aren't hoof trimmings included)

Alpaca, Llama and mohair will work, but you will need to add moisture. The moisture content is crucial for processing – and the exotic fibres, don't have as much

Ensure you avoid any other contamination, baling twine, garbage, plastic bags, etc.

Working with FarmersWe have seen the pellet project as a way to connect with farmers and incentivize them by purchasing the waste wool and create opportunities to discuss management and future quality wool purchases.

We purchase waste wool or bellies & necks for $1/lb – which is higher than the going rate for quality wool in Canada through wool growers at the moment. Producers are generally happy to drop the wool off at our farm, but we will occasionally pick it up as well. In our experience, farmers are so thrilled to have something to do with their waste wool and are open to discussing how to keep the rest of their clip more clean and free of VM.

Packaging

Most businesses and greenhouses selling pellets have them packaged in some form of plastic bag or plastic lined bag. We have chosen to package our pellets in a double walled paper bag. It doesn’t make sense for us to package a natural product like wool in a plastic bag. That being said, there are definitely some down sides to using paper bags, and these things must be taken into consideration for packaging your pellets:

The pellets must be completely cooled before packaging. The pellets will create condensation if they are not cooled completely and that will cause the pellets to puff up and in extreme cases could encourage some mold to grow.

You may want to consider some sort of moisture barrier if the pellets will be stored or sold in a place with lots of moisture. The pellets will become less firm and start to puff up if exposed to significant moisture.

The pellets do smell like raw wool. Now if you are like me, you probably really enjoy that smell - but not everyone else does. I have come back to my vehicle after an afternoon of deliveries and the entire car smells like stinky sheep - so this may be a consideration depending on where and who you are selling to.

If you will be shipping pellets, the packaging must be easily shipped and resilient to any elements.The shelf life of pellets, if not exposed to moisture, would be 6 months - 1 year. The only issue is them losing their firmness and they will become more ‘powdery’ they will not be any less effective in the soil, but won’t hold their shape as well.

The packaging is a significant canvas to share information and education around what wool pellets are and how to use them - I encourage you to use that space wisely.

Marketing

The biggest challenge I have experienced thus far with marketing the pellets is the need for greater education with gardeners and customers on the benefits of the wool pellets. I have found that most ‘wool people’ don’t need any convincing of the efficacy of pellets - but for everyone else you will need to do education in your community.

There are a few avenues for marketing - I encourage you to do your own market research and figure out what sales channel is the most effective for you and your region. We looked at 3 specific marketing options.

Business to Business - we sought out major greenhouses in our region to wholesale our pellets. The goal was to have them do the work of selling and marketing the pellets for us. We had competitive pricing, great terms, and we even included educational materials for the greenhouse to use. The challenges we faced was educating and convincing greenhouses to take a chance on a new product that wasn’t already popular. We certainly had more rejections than positive responses. But in two years we have grown our wholesale businesses to include yarn stores as well.

Direct Sales - we sell the pellets out of our on-farm shop, and also attend farmers markets in our region. The sales have been good, but certainly require more education. We produced and had printed a very large vinyl sign for our market booths and that really changed the way people interacted with us and became curious about the pellets.

We also, surprisingly to me, sell a good amount of pellets online. I had assumed we would be selling regionally - shipping in Canada is not cheap - but I have had people order pellets all across Canada.

Custom Pelleting - we are not doing this at the moment, but it is an option we are considering for the future. We have had many people contact us about pelleting their waste wool for their own uses.

I believe that wool pelleters can be set up and successful in many regions. In fact, it makes sense ecologically to keep the nutrients in the regions they came from - and to support many small businesses with pellet operation, rather than one large business doing it all. This, I suppose, is why I decided to share our experiences and teach this course.

Finances

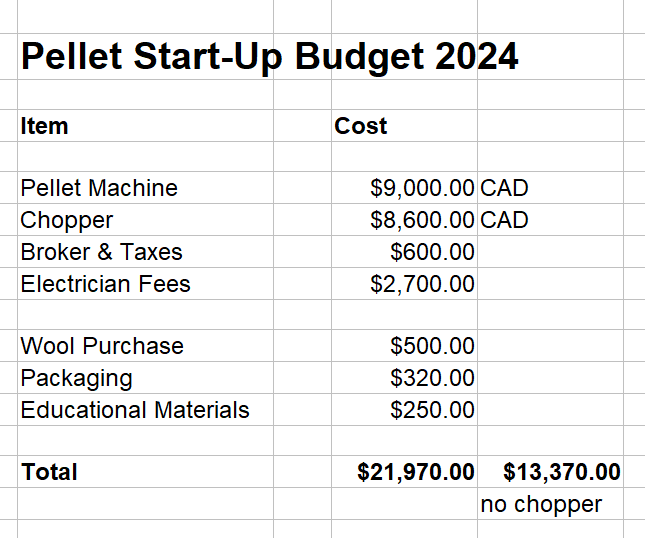

Starting a pellet mill is actually quite affordable - when compared to other wool processing equipment. The biggest benefit being that scouring (washing of wool) is not required.

This is a sample of our start up budget for the pellet operation. The chopper was not available at the time of purchase. But we are adding it in 2024.

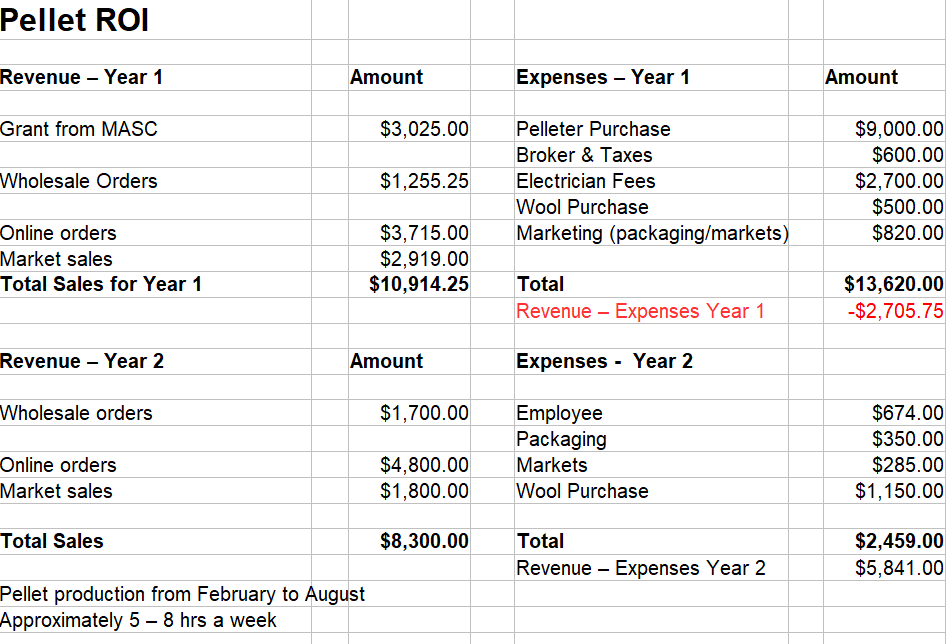

Many ask how long until you recuperate your costs, or what are sales like. I can only share our experience. We applied for and received a grant from our Provincial government. If you can find similar programs for agricultural processors it will help cover some of the early costs.

Here is a sample of our first two years of sales. We had very low overhead costs as we already had significant waste wool and didn't need to purchase much wool than the original $500.

I believe that for us in our zone 3 growing season - the pellets will be a seasonal product only. So we will need our sales to be heavy between April and August.

Troubleshooting

Why are my pellets crumbling and not holding shape? - moisture is essential for pellets staying together. You can add water via a spray bottle to the hopper while making your pellets. It is more crucial to add moisture if you are pelleting in a colder/dry climate in winter.

How many pounds of pellets can I produce in an hour? - Without a chopper you should be able to constantly feed the hopper with wool and produce around 20-30lbs an hour (this includes some time for cleaning out the wrapping wool.

How do I use wool pellets in my garden? - You can directly apply wool when planting seeds - space your seeds out in your row and then sprinkle the wool pellets alongside your seeds. Cover up seeds and wool with soil. 1kg of pellets can be applied to approximately 20-25 square feet of garden.

Pre mix for pots – mix 1/2 cup pellets with 4 litres of soil and add to your pots. Plants that are already potted - sprinkle the wool pellets on the top of the plants and push them down. Or leave them on top for pest repellent (they will not break down as quickly on top of the soil).

How much garden will one bag of wool pellets cover? - 1kg of pellets can be applied to approximately 25 square feet of garden.

How long will wool pellets last in my garden? - When pellets are mixed with the soil they will start breaking down within 3 months. When used as a mulch it will take closer to 12 months to start breaking down. The nutrients in the pellets will release gradually and can last up to a year.

Will there be any transfer of weed seeds from the sheep fleece? - Definitely NOT. The heat used during the process of pelleting will destroy any seeds in the wool. It gets heated up to approximately 200 degrees farenheit

All information copyright Anna Hunter, Long Way Homestead 2024

Business Planning for Starting a Wool Mill

Have you considered starting a wool & fibre processing mill but you aren’t sure where to start? Or maybe you want to add some processing equipment to your existing fibre farm or operation? This is an introductory workshop to business planning for a mill. This workshop will cover the following areas:

Industry overview and opportunities

Marketing considerations

Finances and Funding

Resources and Timeline

Q& A

Course Manual

Business Planning for Starting a Fibre Mill Manual

You can find the full text of the manual after the video.

This manual is Copyright 2022 Anna Hunter, Long Way Homestead

Course Video

Course Manual Content

Table of Contents

Industry Overview and Opportunities

Mills in Canada

Mill Equipment

What is your Why

Defining your Why

Mission/Vision and Goal setting

Marketing Considerations

Who are your customers

Custom Processing / Retail

Market Research

What makes you Unique

Sales Channels

Finances and Funding

Overview of Costs

Startup Costs

Return on Investment

Financial Planning

Resources and Timeline

Water

Wool

Timeline

Introduction

Have you considered starting a wool & fibre processing mill but you aren’t sure where to start? Or maybe you want to add some processing equipment to your existing fibre farm or operation? What are the key considerations for marketing, finances, timeline and resources that will ensure success for your wool & Fibre business.

These resources are based on the experience of Long Way Homestead Fibre Mill and will not reflect the variety and depth of experiences from mill owners across N. America. I encourage you to dig into the work, to research and write your own business plan and to talk to as many other mill owners as you can to acquire a variety of experiences and advice.

Ulitmately, we are writing the history or 'how-to' of small-scale textile processing in Canada. There are no courses or training programs on textile processing, no trade schools on running a processing mill – we are figuring this industry out as we go.

Industry Overview and Opportunities

Mills in Canada

In Canada there are three large mills remaining: Custom Woollen Mill in Alberta, Briggs and Little in New Brunswick, and MacCauslands in PEI. The only other mills in the country are the small and mini mills. The majority of the Canadian textile infrastructure was lost in between the 1920’s and the 1980’s. Sadly, the knowledge and systems for fibre production also disappeared.

Canada produces approximately 3 million pounds of wool annually. The majority of this is course or non-textile quality wool. Our sheep industry is predominantly producing lamb/meat and the wool is not considered an agricultural commodity. Combined with the loss of infrastructure to adequately process wool domestically means that 90% of all the wool grown in Canada is shipped overseas. The Canadian Cooperative Wool Growers purchases wool from producers and then sells it within the international market - but the majority is going to china.

The remaining 10% is being processed by the large and small mills leftover in Canada. There is great opportunity to access more wool, and to produce excellent products both for the niche fibre arts market, but also for the textile and semi-industrial markets.

Mills in Canada all have their own unique business models and structures. Some only do custom processing for sheep producers in their regions, and others do only their own fibre and/or retail production. Some do both. Some mills process exclusively sheep fibre and others only exotic fibre. Determining the opportunities should be a defining feature of a business plan and your market research.

From the Sheep & Wool Survey wait times and access to mills were identified as some of the greatest barriers for sheep producers in marketing their fibre. Many of the mills in Canada are struggling to keep their wait times short, or to keep up with the demand. Many regions across the country are underserved with no mills at all. There is great opportunity to provide a service for fibre producers and to build a thriving business.

Mill Equipment

There are two options for individuals looking to open a wool/fibre processing mill.

Purchasing new equipment

Finding and restoring old equipment

Both have advantages and disadvantages in acquiring and in running. I recommend you begin looking at the options for equipment right away. Talk to other mill owners about their experiences and what they have liked or disliked about the equipment they use. At Long Way Homestead we use Belfast Mini Mill equipment.

New Equipment Advantages

Good working condition

Limited training options from manufacturer

Easier access to parts and repairs

Easier use

Disadvantages

Smaller capacity

Older Equipment Advantages

Larger capacity

Well-constructed / durable

Disadvantages

Repairs and parts can be hard to find

Limited range (in processing)

Harder to find

Training and experience

Small Mill Equipment Suppliers

Belfast Mini Mills (https://minimills.net/)

Ramella (http://www.ramella.com/)

Stonehedge Fibre Mill Equipment (no longer selling equipment)

Marketing Considerations

Marketing is so much more than selling and advertising your product(s). It is the first step after defining your 'why', even more important than crunching the numbers for your future mill.

Who is going to buy your products and what are they all about.

For the purpose of this workshop we are focusing on the first crucial steps of a marketing plan. Of course you will also need to figure out your sales channels, distribution, advertising and/or social media. I encourage you to seek out helpful resources for this part of your business planning.

Who are your Customers

This is the most critical question if your mill business is to succeed. Who are you selling your products or services to. What do they want? What are they willing to spend? How often will they purchase your product? Where do they live? How will you reach them?

Most fibre mills focus on processing fibre into a product that they sell retail, or custom processing for other producers or a mix of both. Put some consideration into what you want to focus on in your mill and what the customer base for those options are.

Custom Processing

There is a large need for more mills to do custom processing across N. America. Many mills have months long wait lists for processing. What is it like in your region? Are there many mills and what sort of processing services do they offer. Some questions to consider for custom processing could be:

Are there many sheep producers in your area in need of custom processing?

How will your customers get their wool to you (are you in an easily accessible region or will it all be shipped)?

How will you build relationships with the producers in your region?

Can you offer custom services that no other mills are offering? (felting, roving, spinning, in house dyeing etc)

Retail or Wholesale

The yarn and fibre industry in Canada is large and growing, and the focus on purchasing local will make any small mill business a hit. As long as you have an effective way of getting your yarn in the hands of knitter, crocheters, weavers and spinners. The mark up on retail yarn is much higher than wholesale or custom processing, however, it requires more work to market and sell this product. Here are some questions to consider for retail or wholesale marketing

Will you sell the yarn/products yourself or will you try to wholesale them through existing stores/shops?

Where will you sell them?

fibre or farm markets: How many will you attend a year, what will your travel and set up look like, can you do that easily? Who will operate the mill while you are away selling at markets?

Bricks & Mortar or on farm store: How close are you to urban centres? How will people learn about your shop? Do you have mill parking, bathrooms, food, signage etc. What will be your operating hours and will you need staff? Will you sell other products or just your own?

On line store: what website / platform will you use? How will you photograph your items? How will you ship your items? How will you manage inventory for an online store. How will you reach customers for your online store?

Wholesale to existing LYS: What stores are in your region? Do they already focus on local or how will they promote your product in their shop? How many times a year would they order yarn/fibre. What are their wholesaling agreements (consignment usually a 70/30 split, or direct purchase at 50/50 retail price)

Market Research

Research should be the foundation of your marketing plan and strategy. The research will be something you can come back to during the other aspects of your business planning. The research will also help you define the aspects of your business that you perhaps are not aware of yet.

Market research can utilize many tools and strategies for finding information that will inform your sales marketing plan. You are not limited to internet or statistical research, but that can be useful as well. For example:

How many sheep farmers are in your region (use stats can, or provincial ag extension website)

How many sheep farmers in your region wish they had access to a mill (use a google survey with a list of questions and ask your local sheep association to send it out)

The market research can be more specific and methodical, or can be more informal and flexible. But it is essential you start these things in some form or another. It should include:

SWOT Analysis

What are the strengths, weaknesses, opportunities and threats of your business

Competetive Analysis

Who are your competitors and what are they doing? This will help you set your business and your products apart from what others are doing.

Buyer Persona / Ideal Customer Avatar

Who are your customers and what are they all about. This research is one of the most informative pieces for how you will market your products and what sales channels you will use.

I find it helpful to actually name and identify the things about my 'customer profiles' that I have researched. For example:

Customer Profile #1 (based on market research)

Katie is a 35 year old professional who loves to knit. She makes about $110,000/year and owns her own home with her partner and her cat. She attends knitting shows, her LYS and a stitch n bitch group. She prefers to ride her bike over a car, and shopping at the farmers market rather than big box stores. She has no aspirations to become a farmer, but she loves learning more about where her wool comes from. She spends between $50 - $200/month on yarn or yarn related items.

Understanding your customers, who they are, what they value, and what their income levels are will help you determine how to be effective at marketing your unique products. You can have multiple customer profiles for your business – but don't stretch yourself too thin. You can't be everything to everyone, and the most effective businesses know who they are and who they want to sell to, and they focus on that.

What Makes you Unique

Chances are you already came up with some ideas on what makes you unique while figuring out the competitive analysis. Now build on that to develop a brand for your business.

Prioritize your brand from day 1 – even if you don't have everything figured out. Define your brand and don't be afraid to stand behind it.

Brand / logo /appearance - work with a graphic designer if you don't' have those skills. (This was one of the smartest things I did in the beginning of our business, and it saved me so much time trying to use software I didn't know). You define your brand, not the other way around. Decide how you want to present your brand/business and be consistent. Take a content creation course (I can make recommendations) and determine from the beginning how you want to tell your story to connect with your customers.

Define your Sales Channel

Finally, you know what your product is, you know who your customers are, you have defined your brand – now what will your sales channels be?

At this early stage of business planning make a list of all the places and ways that you want to sell your product and what you need to do to get it there. Packaging, labels, shipping, product photos, look books, advertising, pattern support. Start big with this list and narrow it down as your business planning takes shape.

Get creative. Just because it hasn't been done before doesn't mean it won't work. (ie. Breed specific subscription)

What is Your Why?

Why do you want to open up a fibre processing mill? What will get you up every morning? What will be the reason you dig deep and do this hard work? Write down your why – and keep it close. Remember it when everything is covered in static and nothing will work. Remember it when you can't figure out why the carder is making a funny noise and you've spent half the day cleaning it. Remember it when customers are frustrated that you can't turn straw into gold – it'll keep you going.

My Why for LWH Field School:

To empower and educate other so that we can build regional, resilient textile systems.

What is your WHY? Here is some helpful words to develop your own why

TO ____ SO THAT ____.

The first blank represents your contribution — the contribution you make to the lives others through your WHY. And the second blank represents the impact of your contribution. Your job is to plug-in the blanks to create your own unique WHY Statement.

Mission/Vision/Goals

Defining a mission and vision statement can act as a guide as you go through the big questions of your business. A Mission Statement defines the company's business, its objectives and its approach to reach those objectives. A Vision Statement describes the desired future position of the company:

Mission: Long Way Homestead is a family owned and operated fibre farm and wool mill in Eastern Manitoba. We produce yarn, fibre and other products to the fibre arts community and provide custom processing services for other sheep and alpaca farmers in Western Canada.

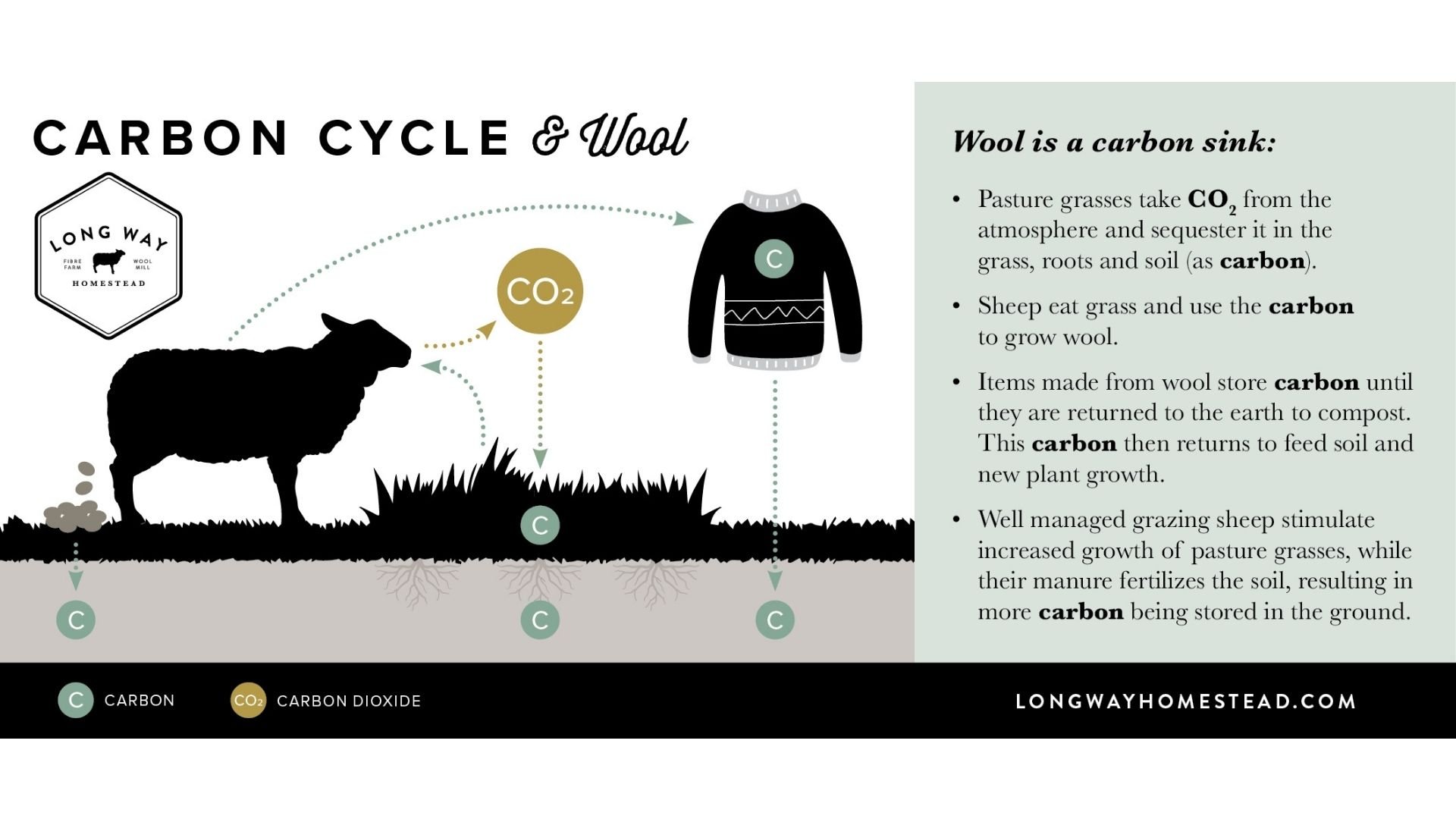

Vision: Long Way Homestead works to promote and build up the Canadian Wool Industry through wool processing and sales, and also through education and advocacy. LWH recognizes the importance of local, resilient textile systems and believes that building capacity and infrastructure in Canada is vital to the health of our communities, economies and climate. LWH also advocates for the utilization of sheep, alpaca, bison and other fibre ruminants in the the management of grasslands, and landbases to build soil health, sequester carbon and mitigate climate change.

Goal setting: I encourage you to make some goals for your potential mill business. They don't have to be big, or grandiose, they can be simple and attainable. What do you want to see happen? Now post them somewhere, maybe in your office, or car, or journal – and don't lose sight of them.

What are your goals for the next year of building up a mill business?

What are your goals for the next 3 years?

The next 5 years?

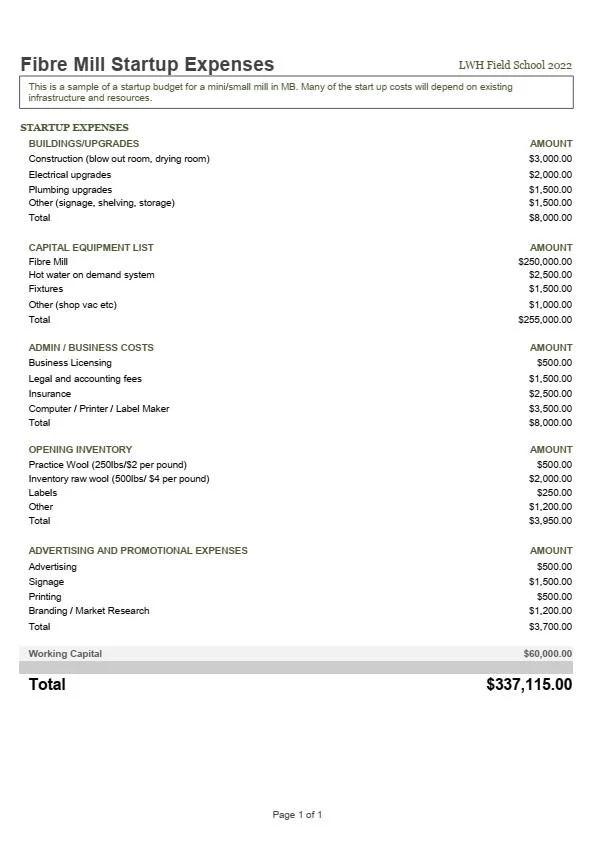

Finances and Funding

I won't lie to you, opening up a wool/fibre mill is going to cost you money, AND the return on your investment (ROI) will take some time. This doesn't mean you shouldn't do it, but hopefully this course will ensure you have a more clear idea of what it will cost and how quickly you can expect to see a return.

The numbers included in this workshop are based on our experience and the experience of a few other mill owners I have spoken with. Prices may vary for every single business.

Overview of costs

The largest costs for a wool/fibre mill will be:

Equipment

Building (if you require a new one, or to renovate existing building)

Practise wool (trust me, you will want to pay for some of it)

At least one full year of capital while training on your machines

Please see the attached sample startup budget (appendix 1)

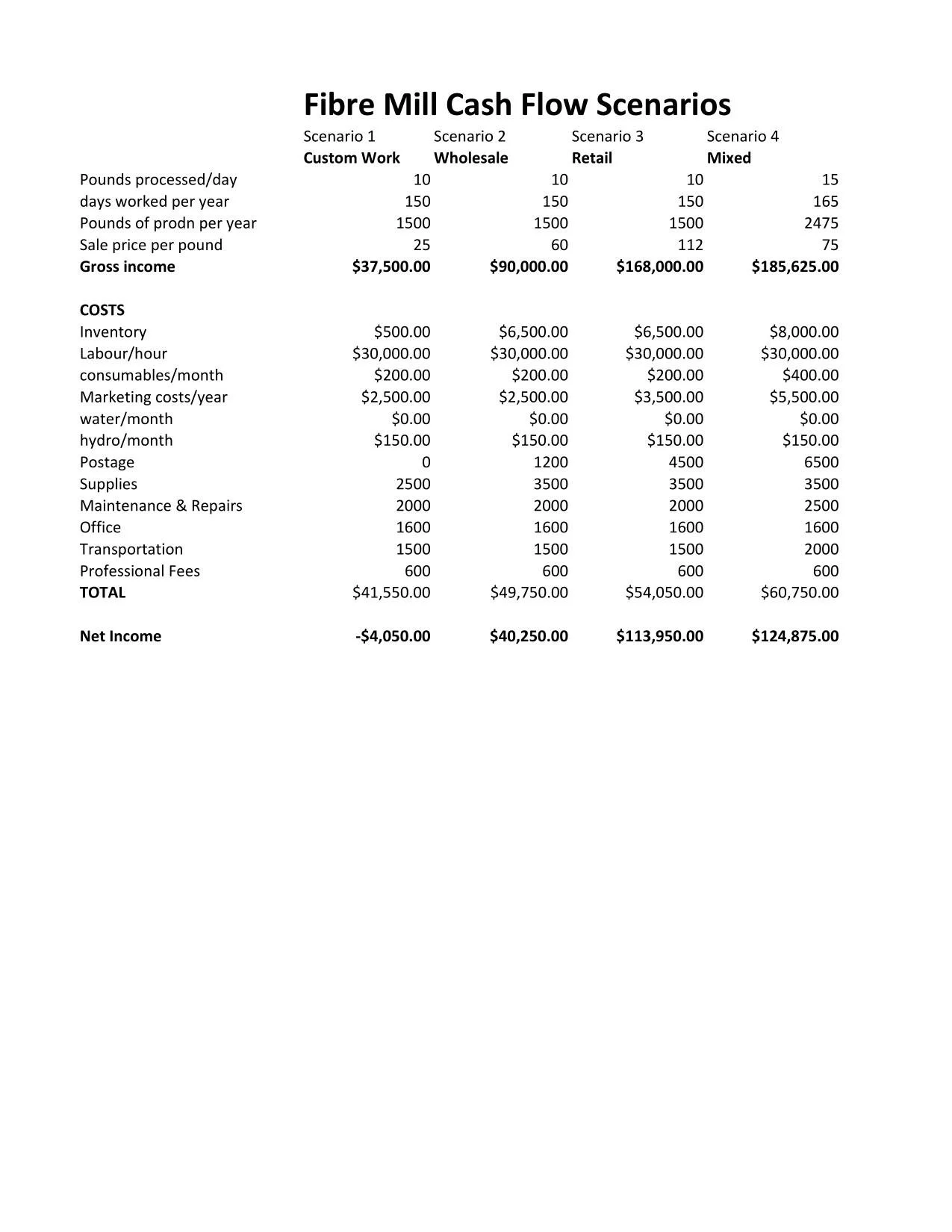

Return on investment

Please see the attached cash flow scenarios sheet.

What are the risks and what are the rewards. How can you reduce the risks?

Reduce the Risks

Find grants or other non-repayable money to help finance the start of your mill. Funding for specialty groups

Start your mill incrementally (carding first, build to spinning)

Business planning courses

Financial planning for success

Having a plan is the greatest piece of advice I can provide for starting a fibre mill. And to be prepared, financially, to learn how to run and maintain your machinery without the stress of having to produce a financially viable business for at least 1 year and 2 is you can afford it.

There is no way to learn everything that is required for making a quality, consistent product without time and practice. If you can plan for a 12-18 month period of positive cash flow (or external income) then your learning will be smoother and without the stress of having to turn a profit.

Resources and Timeline

You have written your business plan, finished your market research, defined your customer profiles and products, nailed down your financial plan - what else is there to know?

There are many ways to make a mill successful, but understanding the specific resources at your disposal, or that you will have to manage will ensure you are starting out on the right path. These are mostly a series of considerations for you to dive into more thoroughly.

Water

The greatest bottleneck for most small/mini/medium sized mills is the scouring process. A significant amount of water is needed to adequately wash the fibre you will process. If your fibre is dirty then every other step of the processing will be problematic and you will spend more time cleaning and troubleshooting than actually processing. Depending on the source of your water and the fibre that you are washing you will have to make decisions that work best for you. Here are some key considerations or questions to ask yourself during the planning process:

What are the specific scouring needs for the fibre you will be producing?

For example: alpaca fibre does not require hot water (no lanolin) so you will not need to worry too much about heating it to the necessary temperature. Alpaca fibre however is more dusty, so a tumbler will be a necessary add-on for your mill

Wool requires very high temperatures (180 degrees Fahrenheit is ideal to remove the lanolin). How will ensure a regular output of hot water in a quantity that is necessary for the amount of wool you want to wash? Industrial hot water tank, hot water on demand, boiling water in addition to tap water etc.

What is the actual composition of your water, and what can you do to balance it out?

This may not seem important, but the ph of your water is crucial to the effectiveness of your scouring operation. Is your water hard or soft? Is there extra iron or other minerals in your water and how does that affect the scouring of your wool. Testing your water beforehand will eliminate some of the troubleshooting later on. There are resources included in this manual for understanding the ideal conditions for scouring wool.

What happens to your waste water?

Most smaller mills are using a very mild soap/detergent and are not carbonizing the fibre. Thus, your waste water is predominantly dirt, manure, Lanolin and a bit of soap. You must have a plan for disposal.

If you are living rurally and operating on a septic system you will most likely need to look at alternatives for waste water disposal. A septic field will most likely be overwhelmed by the quantity of water being disposed.

If you are operating a mill in a more urban centre that has a waste water treatment system, please get in touch with your municipal waste department to determine what/if any requirements they have for mill water disposal.

Many mills will install a ‘grease trap’ for their waste water, as the lanolin/grease can cause issues in your pipes and/or waste systems. Each of these options will be unique to your particular situation, and you should include any potential costs in dealing with the waste water from your mill.

Wool/fibre

The two big considerations are where you will source your wool/fibre for production and will you have regular, consistent access to all the quantities you need.

Once you determine if you are doing retail/wholesale or custom, or a mix of both, then you can start sourcing out your fibre. When you know the quantity of wool you hope to process yearly you will have to ensure you can source and purchase enough to keep you busy. Some questions to consider are:

How will you get the fibre/wool? Will it be shipped (and what is the cost). Will you pick it up and how will you transport it?

Who are you buying from and how do they manage their fibre? Are management practices important to you for your fibre sourcing?

How much will you pay for wool/fibre and what condition do you expect it to be in? (Ie. Skirted, sorted, bagged etc)

What time of year does shearing happen in your region? Will you be able to access the fibre/wool during that time?

What are the limitations of your mill in terms of processing (staple length, crimp, micron count) and what breeds of wool will you hope to process.

Another big consideration is where will you store the wool that is not being processed immediately in your mill? It must be kept dry and protected from the weather, and also not easily accessible by rodents and pests. It is recommended to do quarterly or yearly moth prevention cleaning of your wool storage (and mill) to ensure you don’t have an infestation.

Finally, you should ensure that you have access to a large amount of ‘practice wool’ for the first few months of operating your mill. If you can access as much quality wool and a variety of breeds and qualities then your training will be more thorough.

Energy

Depending on the equipment you use your energy needs will be different. What sort of electricity does your current set up have and how will you accommodate the new energy draw from a mill. If you are considering alternative/renewable forms of energy what will your consistent output be? Depending on your scouring set up, you may need to make adjustments to accommodate hot water on demand or other hot water tanks.

Timeline for mill set up

This will be different for every operation, but this is an example of the timeline for our set up:

Starting in April 2017

6 months of market research, business planning/writing

2 months of researching and visiting mills/Belfast manufacturers to decide on equipment (It was a six month wait time in 2018 for Belfast equipment)

3 months to secure financing

Starting in June 2018

6 weeks of building upgrades and preparation

2 weeks for mill installation and training

18 months of trial and error training

Managing Sheep for Wool Quality

This class features Brian Greaves, Sheep farmer and wool handler with over 35 years of experience. The following topics are covered:

When is it the best time to turn the flock out on spring pasture?

What is best for the grass?

What is best for animal health

Types of pasture management

Set stocking

Rotational grazing

Strip grazing

Managing pasture to help reduce internal parasites

Pasture length

length of time on pasture

Plant species

Selecting Rams to improve fleece Quality, length, Weight

Winter management of flock for health and wool quality

feeding hay to lessen VM contamination.(vegetable Matter)

Shelter

Bedding

Shearing

Timing

Wool handling and Skirting

Storage

There is no manual for this workshop.

Marketing for Fibre Farmers - A Panel Discussion

We hosted a panel discussion in 2019 with 4 different fibre farmers using different strategies to promote their wool.