Wool Pellets - Opportunitites and Considerations

As more innovative ideas emerge for dealing with our abundance of unused or ‘waste’ wool in N. America, many are looking at adding wool pelleting operations to their existing wool based business.

This 1.5 hr workshop will look at our journey and considerations for adding a wool pelleting operation to our business. The workshop will look at:

equipment and infrastructure needs

research on wool in the soil

sourcing waste wool

packaging

marketing

finances

Q & A

Course Manual

Wool Pellet Opportunities and Considerations Manual

You can find the full text of the manual after the video.

This manual is Copyright 2024 Anna Hunter, Long Way Homestead

Course Video

Course Manual Content

Introduction

As more innovative ideas emerge for dealing with our abundance of unused or ‘waste’ wool in N. America, many are looking at adding wool pelleting operations to their existing wool based business.

We initially started looking into wool pelleting as a way to achieve zero waste goals for our wool processing mills. Very quickly it become clear that wool pellets are an opportunity to bridge the gap between our lack of infrastructure for processing wool in Canada and the abundance of wool that is being under-utilized.

We believe that pelletizing wool can be an effective tool in regions across N. America to begin adding value to wool, returning nutrients to the soil and compensating farmers for their work. We hope this workshop and these resources help you in your process and business planning for introducing a pellet machine to your existing or new operation. We hope this manual will help you get started on your own journey and please reach out if you have more questions! (info@longwayhomestead.com)

Equipment & Infrastructure

Pellet machines are not a new invention, many have been pelleting wood, alfalfa, feed, straw, hops, paper and more. The process of pelleting wool uses the same machinery and process as these other common forms of pelleting. The one challenge to pelletizing wool is the fibrous nature and long staple length of wool. Thankfully, there are some engineers out there who have already figured out how to accommodate this challenge.

Most pelleting systems include a pelleter machine – using a powerful motor to push large metal rollers over a die plate that forces the wool down into the holes and out the chute as a small pellet. Due to the fibrous nature of wool, many companies have utilized a chopper to cut the wool up into smaller pieces to make the pelleting process more expedient and less chances for wrapping of wool around the rollers. You do not need a chopper to pelletize, but it will increase production and reduce the maintenance and cleaning on the pelleting machine.

The machinery itself is not specialized (with the exception of the die plates) many have experimented with other feed and/or wood pelleters for their wool pelleting needs. There are a few companies that have set themselves apart in terms of manufacturing specifically wool pellet machinery.

Wild Valley – USA

They patented wool pellets a few years ago and have made a name for themselves as all things 'wool pelleting' at one point they sold pelleting/chopping equipment, but required exclusivity arrangements with buyers and retained a portion of sales (this may not be the case any more). In 2018 their set up was around $35,000 USD

https://www.wildvalleyfarms.com/wool-pellets.html

In terms of other infrastructure and Equipment needs:

Elf Pellet Mills – EU, USA, CANADA

The Elf pellet mill comes with a chopper and a pelleter. They claim that about 100lbs of wool can be pelleted per hour. The equipment and customer service of the company is excellent. The challenges are in the supply chain (equipment and parts coming from Europe) and also the phase 3 power. The machines will not run on phase 1 power like most of the USA & Canada have. If you have a way to convert the power on site, then the equipment is an excellent choice. In late 2021 it was approximately $30,000CAD

https://elfpelletmills.com/wool-pellets/

Buskirk Engineering – USA

Buskirk is who I purchased my pelleting machine from. They are an engineering firm in Indiana, USA. They did not start out intending to work with wool, but have found a bit of niche in making pelleters for wool. They have finished the prototype for a wool chopper and now they sell both. They also have a PTO pelleter option. The pellet mill is $7,800.00 + shipping. The wool shredder is $6,342.00 + shipping. https://buskirkeng.com/

Electricity – your needs will depend on the machine you purchase. We had to hire an electrician to install our Buskirk machine. You will need to wire the mill - 50A breaker on the 220V single phase power for the PM805 unit (this is what we operate from Buskirk)

Space – I recommend a well ventilated space. The machine creates quite a bit of atmospheric dust, we have found that having air flow is important while pelleting, and the space will generally accumulate fibre and dust after the machine has been running. We also recommend the operator wears a dusk mask. Space for cooling pellets is also critical.

Consumables – We use a few buckets and totes for collecting pellets, sorting raw wool and waste from cleaning out the pelleter. A quality hook for cleaning out wool from the pelleter (if you do not have a chopper) and a good scoop for filling bags and sorting pellets. Quality scale for measuring/weighing out your pellets.

Cleaning & Maintenance – without a chopper we spend 10-15 minutes cleaning out the pelleter after every hour ofuse. You will need to grease the bearings and rollers every 40-60hrs.

Wool in the Soil

There are many benefits of using wool pellets in our soil:

increased aeration

increased water holding capacity

slow release nitrogen and other nutrients

decrease in pests like slugs

These are the basics of what wool pellets can do, but understanding the deeper use and effect will be important to speak with confidence to your customers.

There has been a good amount of research conducted by other businesses, colleges and research centres about the benefits of wool pellets in the soil. Many of these studies are published online and easily available:

https://shelburnefarms.org/blog/experimenting-with-wool-as-a-nitrogen-source-for-farming

https://www.uvm.edu/sites/default/files/The-Center-for-Sustainable-Agriculture/wool%20pellet%20info/wool_handout_feb22.pdf

https://www.wildvalleyfarms.com/why-wool.html

https://projects.sare.org/wp-content/uploads/agronomy-12-01210-v2.pdf

Most people have not heard of wool pellets, and so educating the consumer will be important for both marketing the product, but also transitioning from synthetic or other fertilizers to wool.

It will be important to continue studying wool pellets and to observe any positive or negative long-term effects from using wool pellets in the soil.

Sourcing Waste Wool

Many have been drawn to the idea of pelleting because of the excess of wool, or waste wool in our communities. Pelletizing wool is a more affordable option than scouring and processing it into textiles – so it works as an immediate response to the challenges of our wool industries. In our experience this is what works best for pelletizing.

Any wool will work if you have a chopper. If you do not, then you will want to ensure that the staple length is not longer than 5-6”. If it is, the potential for wrapping around the rollers is higher and you will have to spend more time cleaning the machine.

Bellies & necks are simple and easy, and don't generally require any extra prep (just make sure there aren't hoof trimmings included)

Alpaca, Llama and mohair will work, but you will need to add moisture. The moisture content is crucial for processing – and the exotic fibres, don't have as much

Ensure you avoid any other contamination, baling twine, garbage, plastic bags, etc.

Working with FarmersWe have seen the pellet project as a way to connect with farmers and incentivize them by purchasing the waste wool and create opportunities to discuss management and future quality wool purchases.

We purchase waste wool or bellies & necks for $1/lb – which is higher than the going rate for quality wool in Canada through wool growers at the moment. Producers are generally happy to drop the wool off at our farm, but we will occasionally pick it up as well. In our experience, farmers are so thrilled to have something to do with their waste wool and are open to discussing how to keep the rest of their clip more clean and free of VM.

Packaging

Most businesses and greenhouses selling pellets have them packaged in some form of plastic bag or plastic lined bag. We have chosen to package our pellets in a double walled paper bag. It doesn’t make sense for us to package a natural product like wool in a plastic bag. That being said, there are definitely some down sides to using paper bags, and these things must be taken into consideration for packaging your pellets:

The pellets must be completely cooled before packaging. The pellets will create condensation if they are not cooled completely and that will cause the pellets to puff up and in extreme cases could encourage some mold to grow.

You may want to consider some sort of moisture barrier if the pellets will be stored or sold in a place with lots of moisture. The pellets will become less firm and start to puff up if exposed to significant moisture.

The pellets do smell like raw wool. Now if you are like me, you probably really enjoy that smell - but not everyone else does. I have come back to my vehicle after an afternoon of deliveries and the entire car smells like stinky sheep - so this may be a consideration depending on where and who you are selling to.

If you will be shipping pellets, the packaging must be easily shipped and resilient to any elements.The shelf life of pellets, if not exposed to moisture, would be 6 months - 1 year. The only issue is them losing their firmness and they will become more ‘powdery’ they will not be any less effective in the soil, but won’t hold their shape as well.

The packaging is a significant canvas to share information and education around what wool pellets are and how to use them - I encourage you to use that space wisely.

Marketing

The biggest challenge I have experienced thus far with marketing the pellets is the need for greater education with gardeners and customers on the benefits of the wool pellets. I have found that most ‘wool people’ don’t need any convincing of the efficacy of pellets - but for everyone else you will need to do education in your community.

There are a few avenues for marketing - I encourage you to do your own market research and figure out what sales channel is the most effective for you and your region. We looked at 3 specific marketing options.

Business to Business - we sought out major greenhouses in our region to wholesale our pellets. The goal was to have them do the work of selling and marketing the pellets for us. We had competitive pricing, great terms, and we even included educational materials for the greenhouse to use. The challenges we faced was educating and convincing greenhouses to take a chance on a new product that wasn’t already popular. We certainly had more rejections than positive responses. But in two years we have grown our wholesale businesses to include yarn stores as well.

Direct Sales - we sell the pellets out of our on-farm shop, and also attend farmers markets in our region. The sales have been good, but certainly require more education. We produced and had printed a very large vinyl sign for our market booths and that really changed the way people interacted with us and became curious about the pellets.

We also, surprisingly to me, sell a good amount of pellets online. I had assumed we would be selling regionally - shipping in Canada is not cheap - but I have had people order pellets all across Canada.

Custom Pelleting - we are not doing this at the moment, but it is an option we are considering for the future. We have had many people contact us about pelleting their waste wool for their own uses.

I believe that wool pelleters can be set up and successful in many regions. In fact, it makes sense ecologically to keep the nutrients in the regions they came from - and to support many small businesses with pellet operation, rather than one large business doing it all. This, I suppose, is why I decided to share our experiences and teach this course.

Finances

Starting a pellet mill is actually quite affordable - when compared to other wool processing equipment. The biggest benefit being that scouring (washing of wool) is not required.

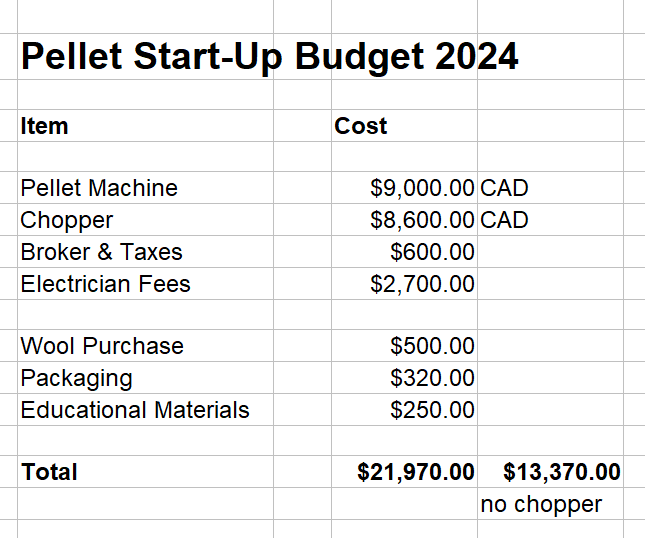

This is a sample of our start up budget for the pellet operation. The chopper was not available at the time of purchase. But we are adding it in 2024.

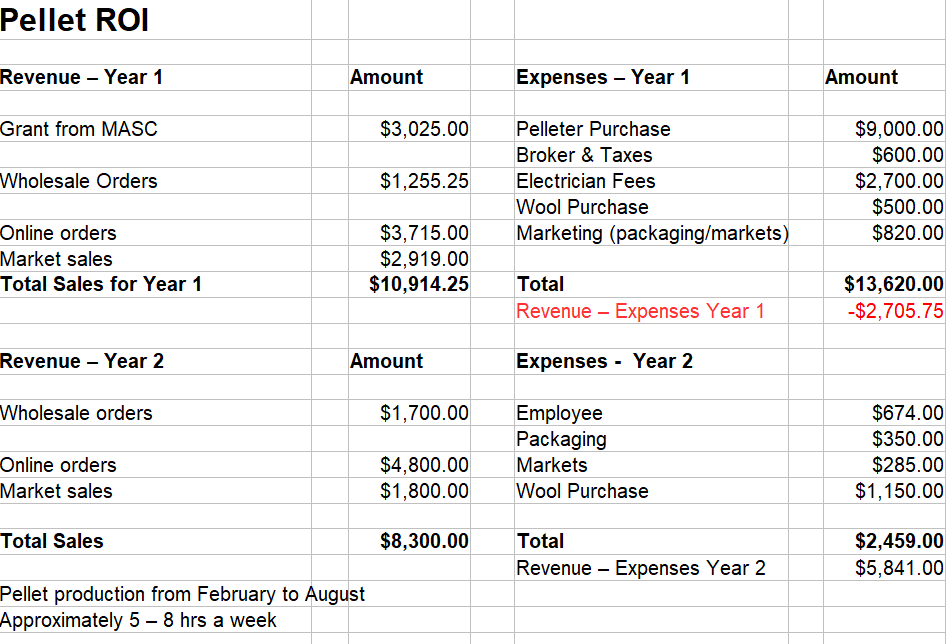

Many ask how long until you recuperate your costs, or what are sales like. I can only share our experience. We applied for and received a grant from our Provincial government. If you can find similar programs for agricultural processors it will help cover some of the early costs.

Here is a sample of our first two years of sales. We had very low overhead costs as we already had significant waste wool and didn't need to purchase much wool than the original $500.

I believe that for us in our zone 3 growing season - the pellets will be a seasonal product only. So we will need our sales to be heavy between April and August.

Troubleshooting

Why are my pellets crumbling and not holding shape? - moisture is essential for pellets staying together. You can add water via a spray bottle to the hopper while making your pellets. It is more crucial to add moisture if you are pelleting in a colder/dry climate in winter.

How many pounds of pellets can I produce in an hour? - Without a chopper you should be able to constantly feed the hopper with wool and produce around 20-30lbs an hour (this includes some time for cleaning out the wrapping wool.

How do I use wool pellets in my garden? - You can directly apply wool when planting seeds - space your seeds out in your row and then sprinkle the wool pellets alongside your seeds. Cover up seeds and wool with soil. 1kg of pellets can be applied to approximately 20-25 square feet of garden.

Pre mix for pots – mix 1/2 cup pellets with 4 litres of soil and add to your pots. Plants that are already potted - sprinkle the wool pellets on the top of the plants and push them down. Or leave them on top for pest repellent (they will not break down as quickly on top of the soil).

How much garden will one bag of wool pellets cover? - 1kg of pellets can be applied to approximately 25 square feet of garden.

How long will wool pellets last in my garden? - When pellets are mixed with the soil they will start breaking down within 3 months. When used as a mulch it will take closer to 12 months to start breaking down. The nutrients in the pellets will release gradually and can last up to a year.

Will there be any transfer of weed seeds from the sheep fleece? - Definitely NOT. The heat used during the process of pelleting will destroy any seeds in the wool. It gets heated up to approximately 200 degrees farenheit

All information copyright Anna Hunter, Long Way Homestead 2024