New Wool Pellet Research

Wool Pellets: A Sustainable Boost for Seed Starting & Garden Growth

A recent research trial from Assiniboine College demonstrates that sheep wool pellets can significantly enhance plant growth when blended into growing media.

Improved Nutrient Supply

Wool pellets contain naturally high levels of nitrogen and potassium that are released slowly over time, helping plants grow well with reduced fertilizer inputs.

Healthier Growing

Moderate wool additions improved chlorophyll content and plant vigor, while also supporting beneficial soil microbes without introducing disease.

Better Plant Performance

When 5–10% wool by volume was mixed into peat-based media, basil plants grew taller, greener, and with greater biomass than those in standard peat alone

Balanced Properties

Wool lowered the density of the growing media, improved aeration, and released nutrients that helped maintain healthy pH and nutrient levels for young plants.

Be an Apprentice on our Farm 2026

Are you an aspiring ecological farmer who wants hands on experience working on a fibre farm with sheep and wool? Ferme Fiola Farm and Long Way Homestead in Ste-Geneviève, Manitoba might be the place for you!

Workplace Culture

Work on the farm is variable and changes with weather or specific events daily. Typically, a normal day would be expected to work 8:30am – 4:30pm with breaks and lunch (usually do 45min family lunch). Sometimes weekdays would be replaced for need to work on a weekend for a farm tour or market event. Sometimes there are evening tasks needed.

Hours and compensation will be discussed and written into the employment contract.

The farms strive to operate with a culture rooted in communication, collaboration and knowledge sharing. They believe that clear communication is the foundation of good work—whether tending animals, maintaining equipment, or working in the gardens/mills. Team members are expected to share information openly, ask questions, and make sure everyone has the knowledge they need to succeed.

Curiosity is encouraged here. They value people who want to understand how things work, who notice the small details, and who seek out opportunities to learn and improve. Knowledge sharing—whether it’s teaching a new skill, offering context on a task, or sharing experiences from own lives – is a value on the farms.

They appreciate hard work and initiative. When a job needs doing, the leaders look for team members who identify the need and step in. This doesn’t mean working without boundaries; it means taking ownership, being proactive, and supporting each other so the entire farm can function smoothly and being flexible to pick up the slack when necessary.

Anna, Christel and Joey love mentoring, teaching and sharing what they have learned, and they also love when someone comes with specific goals and questions.

The whole team can mentor in a range of skills, such as:

Regenerative Land Management

Wool production and marketing

Meat production and Marketing

Mechanical maintenance and fixing of equipment

Growing and harvesting hay

Sheep husbandry

Raising sheep specifically for wool production

Growing and using dye plants and likely more…

For extra specific mentorship wants or asks, hours could be booked and planned on days off and could be exchanged for work hours.

An apprentice will get the most out of this experience if they come prepared to ask questions, be curious and have goals around what they want to accomplish. The team is more than happy to share everything from big blue sky ideas and thinking, to practical skills and farming knowledge.

To Read more about the apprenticeship and for application details check it all out at the Young Agrarian website here.

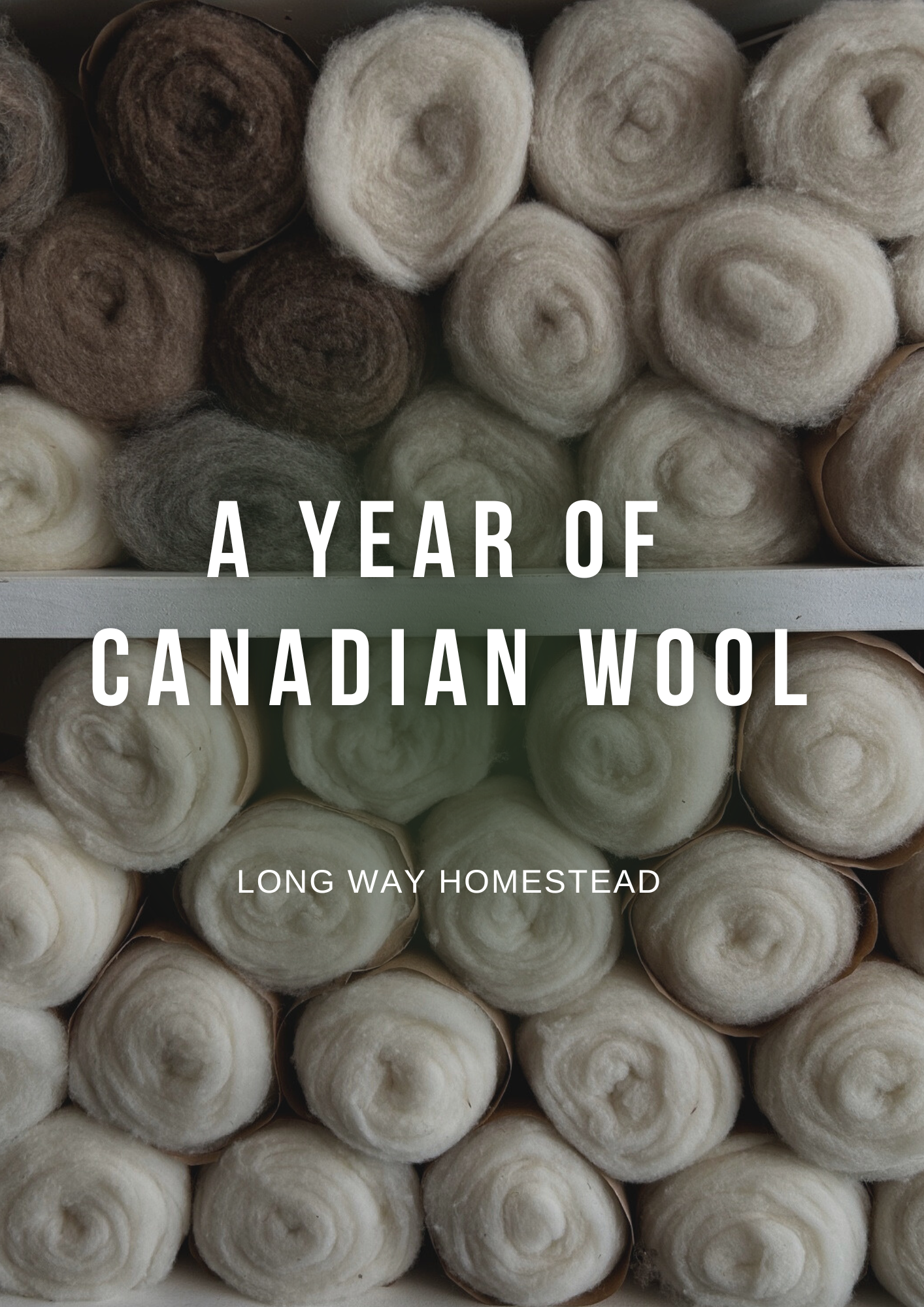

A Year of Canadian Wool

I travelled thousands of km’s this year promoting and speaking about my book The True Cost of Wool. In yarn shops, libraries, book stores and fibre shows I met with hundreds of people excited about Canadian wool and a sustainable future for our industry. It was inspiring to introduce people to the current state of Canadian wool and to witness those ‘aha’ moments with so many people.

I would love to continue travelling, teaching and speaking about Canadian wool, but I’ve been working on some ways to bring that same learning to a broader audience through my new digital year-long subscription.

A Year of Canadian Wool offers insights, research and activities that will guide you through your own exploration of Canadian wool. Each month a new topic will be explored with new content, tutorials and a mix of video, audio, pdf's and other tools to guide you through the various aspects of Canadian wool. Enjoy 12 months of deep dive into the world of Canadian Wool.

I am offerring a special launch price to my newsletter subscribers from now until January 10, 2026. Registering will lock in the price of $15/month for the entire 12 months (you can cancel at anytime).

What You’ll Learn

Canadian Wool History - What is our sheep agriculture and wool manufacturing history. What are the important factors in our wool story and who are the key players.

Using Canadian Wool - What are the best uses for the wool we grow in Canada and how can this inform your fibre arts practise. What processing and manufacturing is required to transform Canadian wool into these different uses.

Connection to the source of your Wool - What are the factors that impact the type and kind of wool we grow in Canada. How can we make a difference in the wool industry if we are a farmer, mill owner, consumer or fibre artist.

Canadian wool from sheep to finished fibre and how it fits into local landscapes, economies, and communities.

Tutorials with simple, hands-on wool tutorials and projects you can complete at home.

Here is a sneak peek at some of the upcoming topics as we dive into A Year of Canadian Wool

Whether you are brand new to Canadian wool or you’ve been working with it for years this new online course offers insights, research and activities that will guide you through your own exploration of Canadian wool. Each month a new topic will be explored with new content, tutorials and a mix of video, audio, pdf's and other tools to guide you through the various aspects of Canadian wool. Enjoy 12 months of deep dive into the world of Canadian Wool

Staggering Statistics

I’ve been thinking a lot lately about how we actually build a movement, a grassroots movement to bring back an industry that has all but died. How do we ‘scale deep’ and expand our ability to grow and process wool while also avoiding the far-to-common consequences of scaling: exploitation (of land, animal and labour), decreased transparency and traceability and connection to the source of our materials.

I don’t have all the answers, but I’m certainly trying to add my voice to this conversation.

If you follow me on Instagram you may have seen this picture I posted the other day.

It felt like Black Friday lasted for 2 weeks this year, so I couldn’t help myself but try and cut through the black friday cheap consumption noise to highlight how we can make a difference with our dollars in the Canadian wool industry.

Doing research for my book The True Cost of Wool, I looked at the studies (unfortunately none have been done in the last few years) and statistics about how much money is spent in our country on yarn each year.

Canadian crafters spent $168 million on yarn in 2023!

This number doesn’t stipulate if it was 100% wool yarn, or cotton or acrylic etc. But it clearly indicates a thriving industry worth millions of dollars.

I put forward the suggestion that if each of us shifted our yearly yarn budget and committed to spending 25% on local Canadian wool it would be $42 million in the pockets of sheep farmers and mills.

That number was staggering to me when I read it. But I wanted to break it down a little further - what does 25% of our yarn budget mean? I asked a few people in my world what their yearly yarn budget was, and when I did the math - it isn’t impossible to commit 25%.

If you spend $150/year on yarn it’s only $37.50 - the equivilent to one skein of farm yarn - maybe it’ll be a nice, cozy toque (hat).

If you spend $500/year on yarn it’s only $125 - that’s like a pair of mittens, a pair of socks and a shawl!

If you spend $1000/year on yarn it’s only $250 - I can picture a beautiful sweater in a stunning palette of natural shetland sheep wool!

And if your yarn budget is closer to $5000/year it’s only $1250 - you could do matching Canadian wool toques & sweaters for everyone in your family!

If we shifted our buying habits to prioritize Canadian wool, it would have a great impact on our industry and community, here are a few:

It would mean less greenhouse gas emissions by limiting the global transport of wool.

More farmers have security on the land to continue stewarding land and sequestering more carbon from the atmosphere - storing it in the soil.

More at-risk sheep breeds thriving and genetic diversity being safeguarded.

More people (mostly women) in rural communities having meaningful work that pays a living wage.

Of course there is more to this conversation that an instagram post can’t cover - financial accessibility, domestic processing, wool quality and availability etc. But I think this post demonstrates that we are willing to spend money on yarn (literally millions) but we need to change the way our system works.

Annual Holiday Market

Join me and my friends at our annual Holiday Event.

Saturday & Sunday

November 29-30

Purl & Hank (2063 Portage Ave)

10am - 4pm

Come hang out with your knitting, make some zero-waste holiday ornaments and do your Christmas shopping with LOCAL wool!

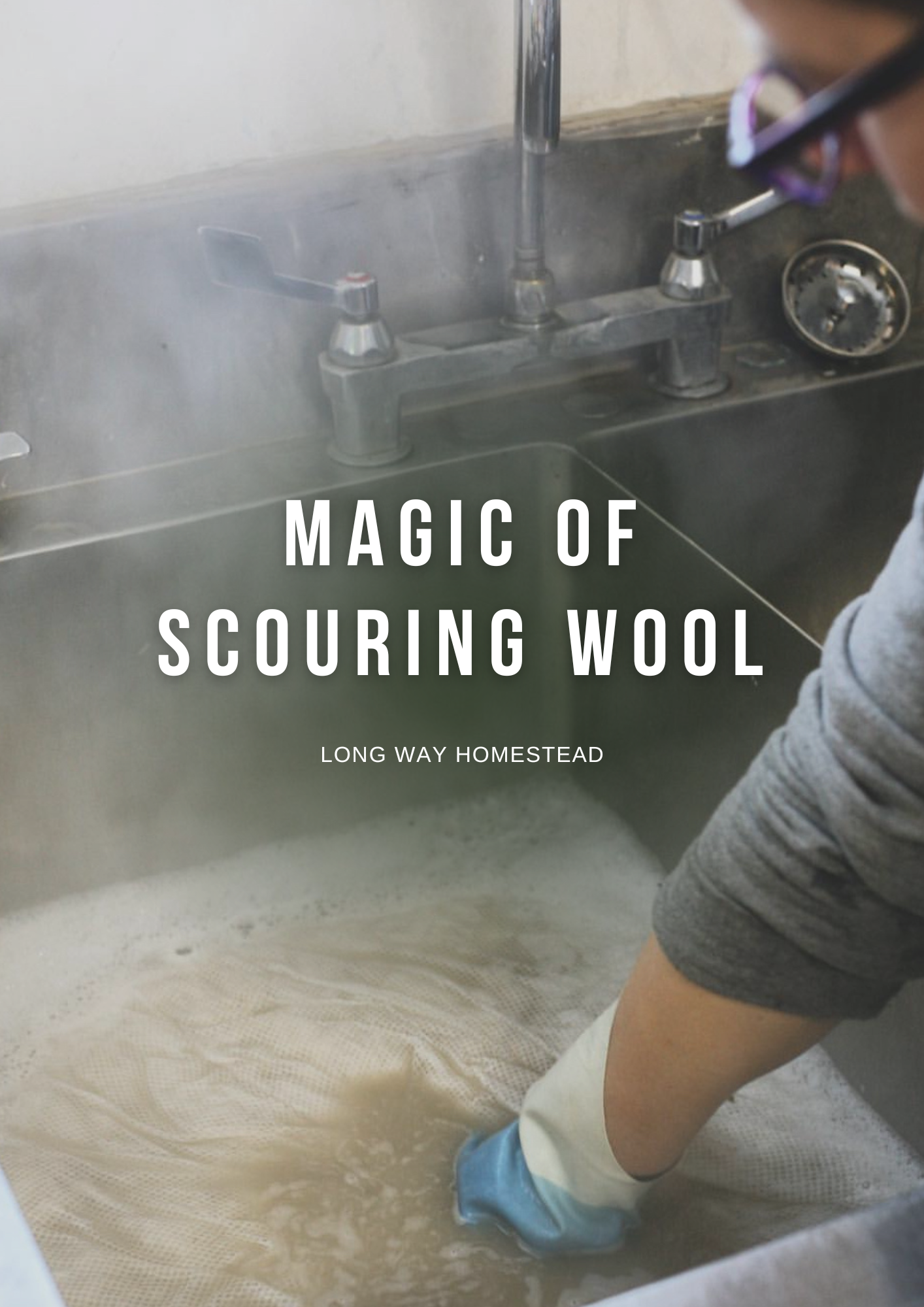

Why is there vegetable matter in my yarn - Carbonization and your wool

If you have ever worked with 'farm yarn' or minimally processed yarn you probably noticed a bit more hay/straw or veggie matter (vm) in that yarn, compared to commercially produced yarn.

All sheep will come into contact with some vm regardless of the management style of each farm, some is dirtier than others, and some cannot be used at all.

a VERY contaminated fleece - sadly this one could not be used at all.

so why is it missing from your commercially produced yarn?

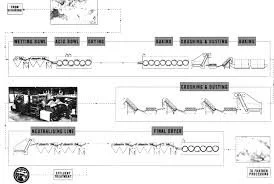

This is because of a process called carbonisation. The process of carbonisation essentially takes the VM that is cellulosic and breaks it down into carbon through these steps:

- immersing the wool in sulphuric acid (H2SO4) at 6% to 7% weight for volume.

- then the wool is baked in dryer at about 120 degrees celsius. These two steps will turn the VM into carbon.

- the wool is then passed through heavy weighted rollers that crushes the carbonised VM into dust.

- To remove the VM dust the fibre is put into a rotary shaker.

- The wool is acidic now due to the sulphuric acid bath. It will then be passed through an alkali solution of Sodium Carbonate to neutralize it.

- Then often wool will be put into a bath of Hydrogen Peroxide to improve the colour for dyeing.

from woolwise

Minimal Processing

In our mill and other small scale mills we do not carbonise the wool. We scour (remove the dirt and lanolin) the wool and run it through our 'tumbler'. This machine turns the fibre to allow any large pieces of straw or hay to fall out.

Then our carding machine will remove some other pieces of hay and straw as it cards the wool. However, it cannot remove all the VM.

We work with farmers to improve their management and feeding to limit VM contamination to begin with - and we do our best to source clean wool.

We don't mind working with yarn that has some VM in it - it reminds us that sheep turn grass into wool!

Folk Fest 2025

It was hot and smokey - but there was some incredible music, beautiful hand-made wares and of course wool!

Naturally dyed yarn and cotton bandanas - next year I bring knitting needles as well!

Our wool floor pillows are always a big hit

Wool Baby Blankets too - they worked great for those that forgot something to sit on!

Watching Ani Difranco perform - 20 years after the last time I saw her - was a total highlight!

Fibre & Farm booth - with my favourite booth mate Christel of Ferme Fiola Farm!

My favourite little folkies!

We are Hiring - Wool Mill Operator

We're Hiring: Wool Mill Assistant (Part-Time)

Location: Long Way Homestead, Eastern Manitoba (35 minutes from Winnipeg)

Wage: $20/hour

Hours: Approximately 20 hours/week

Start Date: Flexible — Late Summer/Early Fall 2025

Application Deadline: Open until filled

To Apply: Send resume and cover letter to info@longwayhomestead.com

About Us

Long Way Homestead is a family-owned and operated fibre farm and wool mill committed to regenerative farming and sustainable textile production. We produce high-quality, fully traceable wool products while building a business that contributes meaningfully to our local community.

Job Overview

We are looking for a part-time Wool Mill Assistant to join our small team. This is a hands-on role working in our processing mill, with potential for full-time employment for the right candidate. If you’re interested in working with natural fibres, learning new skills, and supporting a values-driven small business, we’d love to hear from you.

Key Responsibilities

Operate and maintain industrial wool processing machinery

Perform physical and repetitive tasks including lifting, sorting, and cleaning fibre

Work independently and stay on task with minimal supervision

Follow safety procedures and take direction well

Qualifications & Skills

Ability to work on your feet for full shifts and perform physical labour

Reliable transportation to our rural mill (we are not on a public transit route)

Strong work ethic and self-motivation

Team player with good communication skills

Experience with fibre arts or knowledge of wool is a bonus, but not required

Additional Information

We are committed to creating a welcoming and inclusive workplace. We actively encourage applications from individuals who identify as members of groups with historical and/or current barriers to equity.

Fibre & Farm Market - Saturday, July 26

Fibre & Farm Market

Saturday, July 26th

10am - 4pm

Long Way Homestead & Ferme Fiola Farm (1/2 mile from each other in Ste. Geneveive, outside of Winnipeg)

**The event is free, but we will have a donation box - all the funds will go to support the Rainbow Resource Centre

Come for a day of farm and fibre mill tours, hay rides, sheep snuggles and some excellent products from local farms and fibre artists. There will be light snacks to purchase, bathrooms on site, and the event runs rain or shine. Check out our awesome list of vendors:

Ferme Fiola Farm

Long Way Homestead

Cloverdale Forge

Hundredfold Farm

Bear & Bunny Yarn

Apothecandy

Smash Knits

Amanda Borealis

Purl & Hank

Wild Woods Pottery

Moon Dips Candles

Fireweed Fibre Co

White Spruce Creative

And Pretty Things

Accessibility: We are constantly working to make our facilities accessible. The driveway, walkways, dye studio and outdoor workshops spaces are grass and gravel and accessible by wheelchair. The outhouse, indoor studio space and wool mill all have one step access. We are working hard to improve accessibility on the farm, thank you for your patience.

Check out these photos from some of our past Fibre & Farm Markets!

10 Year Anniversary - Long Way Homestead in Manitoba

This is part personal reflection on the last 10 years, part photo gallery (Cause my kids were so damn cute as little ones) and part links to luke’s past blog posts - if you haven’t read them you definitely should - he is incredibly funny.

On May 15, 2015 Luke and I and our two kids and small u-haul of stuff showed up in Manitoba to start a new chapter of our life as homesteaders/farmers. We had no idea what we were in for, but we had big dreams and we were ready to go.

We didn’t necessarily have a plan to ‘farm’ in terms of it being a business, we mostly wanted to just grow our own food, learn some of those important self-sufficiency skills and have room for our kids to grow up (a little feral).

We found our home/farm very quickly after arriving in Manitoba - and although we really had no idea what we were looking for, and perhaps would’ve made a different decision now that we do know - we moved to our farm on June 23rd, 2015.

Two weeks later we picked up our first 6 baby chicks. They lived in a cardboard box in our family room under a heat lamp. (That was a quick lesson - keeping chickens in your house is really quite gross once they get bigger, I don’t recommend it).

We learned a lot that first year:

Poison Ivy grows everywhere

Prairie sunsets and thunder storms are incredibly powerful

Our soil is mostly clay (and our farm is mostly swamp)

Food always tastes better when eaten outside, around a fire

Year 1 - 2015: New home and new chicks

A lot of people say chickens are the gateway animal for farming, and it’s true. There have never been chickens that are so well cared for and taken care of as those first 6 chickens we had. They went everywhere with my kids (whether they wanted to or not) including sled rides in the winter, we built the nicest chicken coop in the world (it has cedar shingles of course), and then everything changed on December 13, 2015.

Our first homegrown egg.

After that first egg was thoroughly enjoyed we realized we could totally do this… we moved on to pigs and more chickens. And by that spring I knew I wanted to have a sheep farm and start growing and producing wool.

The first set of pigs and the ‘moveable’ pasture pen we made for them.

After the pigs arrived and I started meeting with other farmers to figure out what kind of sheep I wanted, and what was required to have them, we realized we would need some infrastructure.

That is when our community really showed up for us. We launched our first kickstarter and within a few days we had raised enough money to build fencing, a barn and buy our first flock.

I have always been humbled and honoured by the support of those in our community. It has always been clear that we are doing this alongside others - and our wins are also your wins. We are so thankful for the new friends this move has brought into our lives.

That summer we built fencing - Luke and his brother Rich pounded every post of our first pasture into the ground with their grandpa’s old mallet. We had different friends and family come out and help us with different aspects of this ‘barn raising’ and we couldn’t have done it without all of you.

In the summer of 2016 we brought home our first fibre animals. We had two llamas and 4 sheep.

Of course it was nothing like I imagined. The llama jumped the fence the first 6 hours we had her, and the sheep were so skittish they wouldn’t come anywhere near us.

But we had nothing to do other than figure it out - and that first year I spent every spare minute out in the field with my sheep (and a camera in my hand).

I’ve spent considerable time in the last week reading through all my old farm journals and looking through photo albums. Trying to remember the time line clearly, or some funny story that I hadn’t thought of in a while.

A lot of those early years was figuring it out. Writing down a LOT of notes, and then trying to determine if I was seeing a problem or just something normal that I didn’t know yet. It’s a little bit like parenting in the beginning - you wonder if every cough or cry is a problem and you obsess over whether they are eating, pooping, sleeping enough. But all that observation is what really creates understanding and before you know it - it’s just another Tuesday and you aren’t worried about all those things.

In the spring of 2017 we had our first shearing and our first harvest of wool! I can still remember the joy and excitement of that first shearing day - Luke was away for work and so three of my closest friends showed up and helped make that day happen - and it is still among the top 5 moments of my time here in Manitoba.

After that first shearing and discovering there were no wool mills in Manitoba - I became laser focused on opening up a wool mill.

A year later and a lot of work - we finally had our mill. We launched in July of 2018, and again we were surrounded by a community of support.

The next few years were actually a bit of a blur, here is the quick version:

The mill was a steep learning curve and kind of kicked my ass

Luke started a new business crating, installing and shipping art and it was a huge success until….

Covid-19 shut down the museum/art world, he moved into the mill full time and we weren’t sure if the business would survive

We continued to add sheep, llamas, chickens, cats and pigs to the farm

People picked up new hobbies during their time at home and all our hard work started paying off as we finally figured out how to make yarn

We opened up a field school program dedicated to teaching textile growing/processing courses

We added a wool pellet mill to our operation to achieve zero waste and to add value to the wool

Anna wrote a book about sheep farming and wool across Canada

Luke built an outdoor dye studio and a guest cabin

We started offering fibre artist in Residency programs

Partnered with others in our community to offer on-farm educational and market events

We are spending today celebrating as a family - we have some big wins that I hope to share at a later date. It’s been great to reflect on the past - and to look towards the next 10 years and all that will come.

I’m so grateful for all of you that have cheered us on, supported our new projects - and believed in the kind of work we are trying to do!

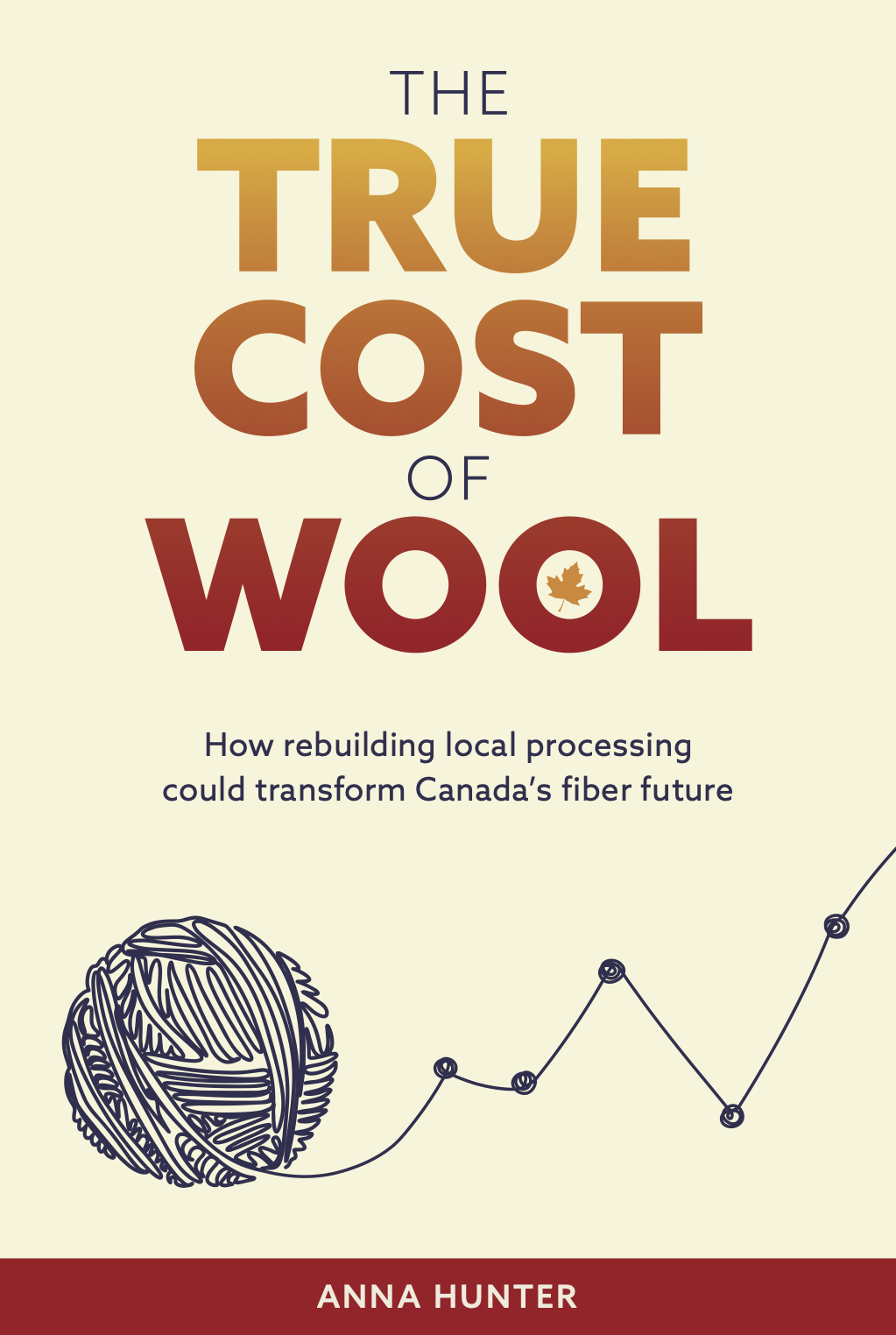

Book Launch - True Cost of Wool

The True Cost of Wool is almost here (release date June 10) and I hope you will join me for the book launch!

If you won’t be in Manitoba, you can also catch it as a live YouTube stream.

Details of Book Launch

Join Anna Hunter for the launch of The True Cost of Wool: A Vision for Revitalizing the Canadian Industry (Nine Ten Publications).

Friday Jun 13 2025

7:00 pm

McNally Robinson - Grant Park in the Atrium | Streaming on YouTube

This event will be hosted live in the Atrium of McNally Robinson Booksellers, Grant Park and also available as a YouTube stream.

At a time when Canadians are rethinking where our goods come from, Hunter reveals a striking disconnect: 90% of Canadian wool leaves the country while 95% of yarn is imported. This timely investigation traces what happens as wool is transformed between farm and finished product. Whether you're a crafter or fibre artist or simply curious about where your textiles come from, this book will forever change how you see a ball of yarn. The True Cost of Wool isn't just about understanding a complex supply chain—it's about reimagining a future where what we wear connects us to land, community, and a more resilient textile economy.

Upcoming Teaching and Speaking Events - Find a date near you!

I am really looking forward to some upcoming speaking and teaching opportunities. Hopefully you will have an opportunity to attend a workshop or lecture in the coming months - where ever you might be!

Vancouver, BC - From Farm to Yarn

Saturday, April 19, 2025

12:45pm - 3:45pm

West Coast Knitters Guild

Gibsons, BC - From Farm to Yarn

Tuesday, April 22, 2025

5pm - 7pm

Persephone Knitting Group

Saskatoon, SK - From Farm to Yarn

Saturday, May 3, 2025

11:30am - 1pm

Wildflower Women’s Homestead Conference

Knit City Montreal

May 16 - 18, 2025

Breed Specific Knitting - More info here

Farm to Yarn - More info here

The True Cost of Wool - More info here

We are always open to online or in-person speaking and teaching with your group - you can see the full list of presentations and workshops here.

I will be booking book-tour stops across Canada for the upcoming True Cost of Wool book. If you have a yarn shop, independent book store, knitting group or guild and would like to organize a book tour event please reach out info@longwayhomestead.com

A note about Canadian Wool and the new USA Tarrifs

I’ve been tagged in countless posts on every social media channel about what are good Canadian yarn businesses and who should I support now that these tariffs have been put in place. I wanted to add some information and context. The timing is interesting because I have been working for the last year on a book about the Canadian wool supply chain and I’ve been immersed in the historical and current day reality of globalized trade and how it affects our wool and yarn industry.

As many of you know I’ve been promoting Canadian grown and milled yarn for a very long time - it isn’t a new reaction to tariffs its been a long-time commitment to a local fibre economy and to building up regenerative wool value chains in our own communities. I am not motivated out of a sense of national pride, but out of an environmental and socially conscious belief that local community development, meaningful work and limited carbon output is necessary for our long-term viability on this planet with limited resources. I believe that we need a long-term investment in infrastructure for our textile and wool industry - and I hope that this moment of looking inward will bring about that investment in our own industry.

So here we go - where to find Canadian wool and yarn.

If you want a truly 100% Canadian wool yarn - meaning it was grown by Canadian sheep farmers and milled by Canadian workers in a Canadian mill your options will be limited, but there are some incredible places to find it. I encourage you to check out the province by province database on www.canadianwool.org (a national non-profit that I started a few years ago that works to advocate for Canadian sheep & wool) .

This list includes sheep farmers, mills and wool brokers and we have a list of certified wool partners here - you can guarantee that this is 100% Canadian wool.

These farmers and mills are the BEST option for investing in your local wool economy. And we/they have been trying to promote their products and the impact of local wool production for years. I’ve made a large list here of local wool/fibre producers - but I’m not going to include links because that would take an AWFUL lot of time and I have sheep to feed and wool to mill - so I encourage you to look them up yourself. (If you want to be on this list send me an email - your ommission is only a function of my time and brain capacity)

Once we go beyond the farmers and mills that have a fully traceable supply chain it gets a little more complicated to understand what is truly Canadian. Over the past 150 years our ability to grow and manufacture everything we consume has changed - the regional self-sufficiency model was replaced by off-shore labour and manufacturing at a reduced cost which meant higher profits - some believe this is an infinitely better system (and we can debate that later). But it explains why we don’t have the capacity to manufacture what we grow domestically.

The majority of the wool yarn that you purchase at large chain stores (michael’s/walmart) and even at your small LYS is comprised of wool that was grown off-shore. Most of the Merino is grown in Australia, but other popular wool yarn brands contain wool from Peru, China, Italy, South Africa and more.

It is sold and bought on the commodity market and categorized by breed, staple length, micron count etc. It is then cleaned and carded in mills - most of these are in China (they are the worlds largest wool manufacturer) and then the carded wool top is usually shipped to other mills where it is spun into yarn. Here is where you have to do a bit of digging and research to understand where that spinning happens.

I encourage you to reach out to your favourite yarn companies and ask them where the processing happens - not because you want to avoid USA products - but because we need to normalize this type of transparency in the wool value chain. (Also, I encourage you to buy my True Cost of Wool book that is coming out in September 2025 because I dive into this in a more meaningful way).

Most of the Indy-dyed or hand dyed yarn is wool grown, cleaned and carded elsewhere, but spun in a large mill in Ontario. The wool is not Canadian and only part of the production is done in Canada, and then the dyeing is happening by entrepreneurs and creatives in Canada.

The big box yarn brands that are spun in a mill in Canada but using wool and fibres sourced elsewhere include:

Bernat, Patons, Lily Sugar and Cream, Coats & Clarke, Caron, Phentex

Then we have the individual yarn brands that are distributed by a Canadian distributor but the ENTIRE process and raw materials happen elsewhere include (some of these may be US companies but distributed by a Canadian company):

Berroco, Estelle, Lang, BC Garn, Erika Night, Manos Del Uruguay, Lano Gato, Nordik Yarn

(I know this isn’t an exhaustive list - but I encourage you to ask the hard questions of your yarn stores and yarn dyers)

So what does this mean? Well I think it highlights how limited we are for options in our own communities. We have a basically non-existent manufacturing industry for managing and dealing with our 3 million lbs/year of wool grown locally - and our wool has become completely de-valued.

I hope you will reach out to your local sheep farmer or wool mill and shop from them - but not just today when we are all fired up - but we will continue to support our local sheep and fibre farmers. And let us collectively push for more infrastructure to manufacture the products that we want locally - talk with mill owners and industry leaders who have some great ideas on how we can move this forward through strategic planning, environmental regeneration and collaboration.

This was a group of us at the anti-FTAA (free trade area of the americas) protest in Quebec City - I’ve been a long-time advocate for local systems and against unfettered free trade.

If you want to learn a bit more then I recommend you check out some of the work I’ve done in the industry. You can read more here, or here. And if reading isn’t your thing - then maybe check out my online lecture about the True Cost of Wool or the history of wool industry here.

You can support my work and read more indepth writing on my patreon - or just simply check out my online shop here.

This was a group of us at the anti-FTAA (free trade area of the americas) protest in Quebec City - I’ve been a long-time advocate for local systems and against unfettered free trade.

Traceability & Transparency

Traceability & Transparency

Ok here is a little experiment - grab the skein/ball of yarn that is closest to you and take note of what is on the label. Brand/logo, name of yarn, meterage/yardage, weight, gauge, washing instructions - does it include the information about where the wool (or other fibres) were grown? How about where it was processed or dyed? If it’s an indy-dyed skein it probably says “small batch processed in Canada” or something similar, but does it have any info about where it actually came from?

Chances are a lot of the wool you or I work with does not have that information included on the label. If you are particularly discerning you might check out their website and see if they include traceability info there. Chances are you might find some information - but the larger the yarn company the harder it is to track down that information.

So why does it even matter?

Maybe it doesn’t - and that’s ok too. For lots of us fibre work is how we relax and maybe unplug from the constant barrage of stress in the world (and there has been a lot of that this week right?). But I believe that most of us want to make ethical, choices in our purchasing. We want our yarn to be soft AND from a farm that upholds standards of care for its sheep. We want our fibre to be well prepared AND processed by someone who was paid a living wage. We want our yarn to be fantastic colours AND to trust that the effluent water was treated properly before entering waterways.

I have spent a good portion of the last 4 years trying to document and research this information within our industry. To document the value chain that our wool travels through. And this info is really hard to find.

I don’t believe there is some large nefarious ‘big wool’ scheme happening in the world. I imagine that we don’t see that information front and centre because not enough consumers are asking about it.

But the further removed we are from the value chain of our wool and our textiles the less we understand who is making the decisions and what factors influence their decision making.

Here is what some of the numbers tell us.

In 2022 - 1,357,900kg of wool was purchased from Canadian sheep farmers and 620,162Kg of wool was sold and exported off shore (Agriculture Canada). Once that wool is bought and sold we don’t have any more information about where it goes or how it is transformed, it joins the global wool pool. The best we can hope for is that farmers were paid adequately for the wool when they sold it.

In the same year $4.4 million dollars worth of processed wool yarn was imported to the country by some of the bigger yarn companies out there. That is obviously the wholesale cost of yarn, and when you double, triple or more that figure we can see that millions of dollars of wool is being imported into the country.

Without transparent information from the companies selling us our yarn, the only information we can glean are the weights and dollar amounts from Statistics Canada. We have to assume that the value chain spans thousands of miles, connecting the farm where the wool is grown, the mill where it’s processed, and the dye houses that transform it into yarn. And our only option is to TRUST the companies that are selling it to us.

That trust is a bit hard in a globalized capitalistic system - where profit is the key driver. And the greatest way to maximize profit is to reduce costs - and that can be done by outsourcing labour to lower-cost economies with less oversight.

So if we (as yarn companies) want to build in that trust and encourage ethical sourcing of wool and yarn we have to prioritize transparency and traceability. And as consumers we also have a role to play - we need to start asking yarn companies and local yarn stores where the wool is coming from and how it’s processed. If we collectively demand those answers it will become common practice to include value chain information.

On our farm and in our mill being transparent with our customers about the process involved from sheep to yarn to waste is a priority. This is essentially the impetus for my next book true cost of wool. But you can also check out our full Traceability & Transparency page on our website here.

Big Bluestem Yarn

Welcome to the newest yarn in our traceable Canadian yarn line up.

Big Bluestem

3-ply DK weight

235m/100g

Mix and match minis 70m/30g

Naturally dyed using plants and minerals we grow on our farm in Eastern Manitoba.

Polypay wool is known for its equal parts softness and body. Producing a yarn that provides loft and bounce (thanks to its dorset influence) but also will be fine and wearable (thanks to the rambouillet and targhee influence).

Why Big Bluestem?

This new yarn is named after a dominant grass found in the tall grass prairies of our land base. The plant is tolerant of heat, drought and fire. The roots of the plant can reach up to 5 feet - an effective way to improve soil health. These roots can store a large amount of fixed carbon and even when the plant dies some of the roots remain in the soil for hundreds of years as organic carbon humus.

Tallgrass prairies are an endangered ecosystem in Canada with only 1% of the original habitat remaining. Much of it has been plowed under for conventional agriculture - but using plants like Big Bluestem can work to restore tallgrass prairies and add ecological health to our land.

The Polypay breed is a dual purpose sheep and was created to produce good quality meat, but also beautiful wool. It's name actually means "many ways to provide return on investment" It is a mix of Targhee, Dorset, Rambouillet and Finnsheep genetics.

Polypay flock at Silverbend Ranch

We purchase our polypay wool from a local Manitoba farmer and minimally process it here at our mill as a semi-worsted 3-ply yarn. This yarn is perfect for your outerwear projects like sweaters, mittens, hats or shawls and many will find it fine enough to wear next to skin.

We have dyed some mini skeins in a stunning rainbow of naturally dyed colours - perfect for your colourwork project!

This yarn is made with wool from a Polypay cross Rambouillet flock in Western Manitoba. The farm - Silverbend Ranch has won numerous awards for its ecological farming work and managing sheep for wool quality and soil health has always been a priority for this farm.

We believe that traceability and transparency are crucial for our yarn and wool products. We visit the sheep farms that we purchase wool from and work with the farmers to understand how they manage both animal and land. We value the work that sheep producers do and work to pay them above market rates for their wool.

We want you, the consumer, to have a closer connection to the farm and sheep that your yarn is coming from and to have a greater understanding of the process involved in getting from sheep to your hands.

2025 Calendar is here!

2025 Calendar

Many of you have asked about our annual sheep calendar - I usually always have it available for the fall markets and it was definitely missed this year.

Don’t worry - the calendar is coming.

I showed up at the Manitoba Fibre Festival and realized I had completely forgotten to put the calendar together. But pictures have been chosen, and it’s being sent to the printers and ready to ship out by October 25, 2024.

Long Way Homestead Calendars feature our flock of Shetland Sheep and guardian llamas. With beautiful photos, this calendar gives you a small sense of what raising sheep throughout the year looks like.

The calendar is 6" x 9" (vertical) and fastened with a jute cord.

NEW Book - True Cost of Wool

New Book Project

I’ve been working on a new book. Actually - this was the first book idea I had before I signed the contract to write Sheep, Shepherd & Land. But at the time it didn’t seem like the right fit - so it’s been something swirling around in my brain for a long time.

The concept of the book was originally based on a lecture that I’ve been doing for many years - The True Cost of Wool

Many years ago (I think it was early 2019) I was working in the mill and received a DM from someone on Instagram making a comment about how expensive my wool was. It wasn't the first time I had heard this critique so it didn't bother me. I wanted to write back "Do you know what goes in to making this yarn? And the 'cheap yarn' you are referencing doesn't require any less resources - it just means you are not paying the TRUE COST of that yarn"

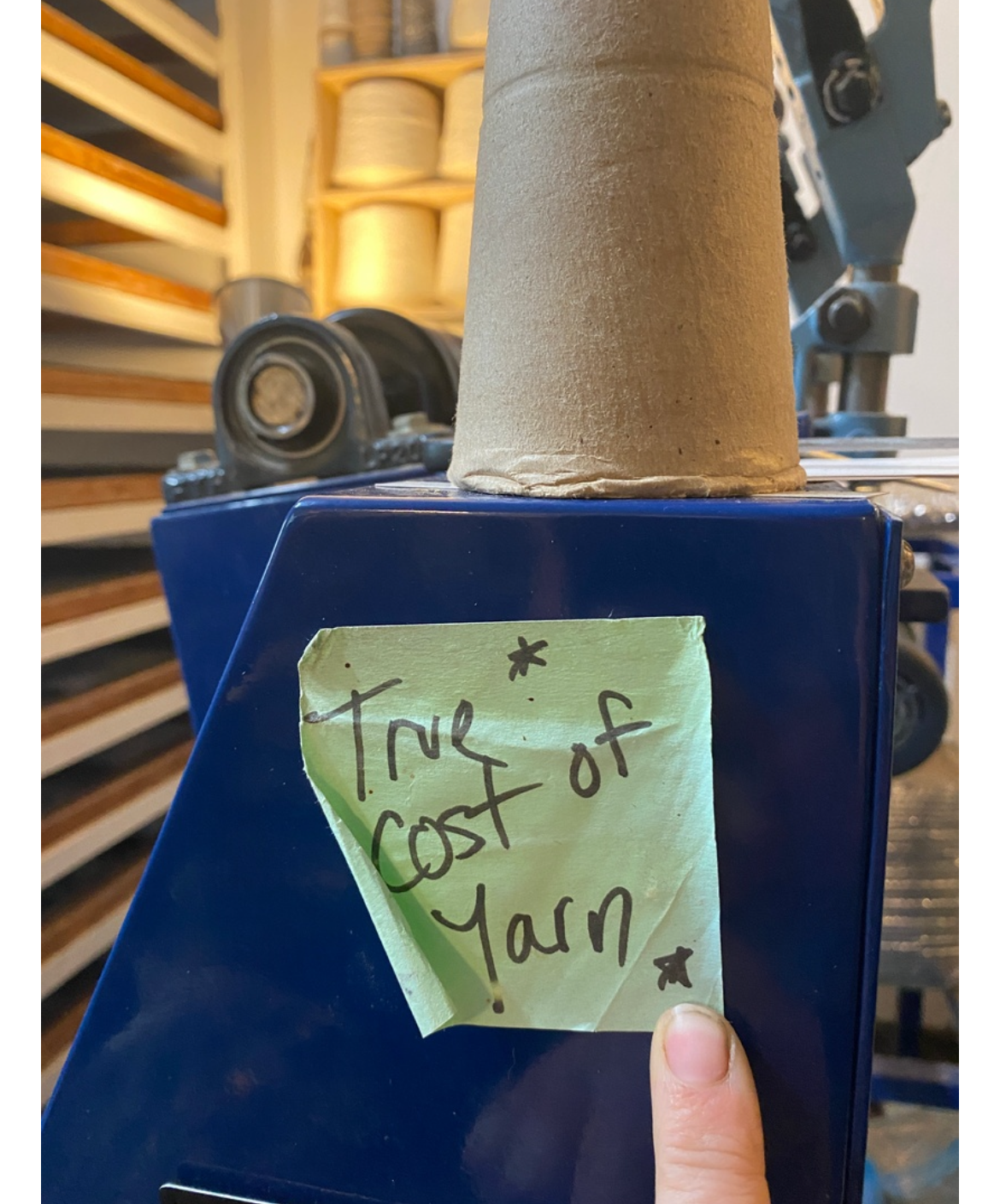

I didn't respond with that - but I jotted down a little note to myself and stuck it on the cone winder machine.

That sticky note and the feeling I was left with from that conversation was this idea that as knitters/crocheters/fibre artists we don't often realize what it actually costs to make yarn - and how and who is taking on those true costs.

I decided to dig into that question and try to expose the supply chain and the costs associated with making yarn in my lecture. The suggestion was made that I turn it into a small book/booklet and basically dig deeper on the research and make it available in book format.

I’m working with Nine Ten Publications again and so thankful that such a supportive publisher exists and they are keen to get this information out into the world. I don’t have a date of release yet - but my first manuscript deadline is fast approaching. If you want an early look into this work you can support my research and writing on Patreon.

Fibre & Farm Fall Market - Saturday, Oct 5, 2024

Fibre & Farm Market

Saturday, October 5th

10am - 4pm

Long Way Homestead & Ferme Fiola Farm (1/2 mile from each other in Ste. Geneveive, outside of Winnipeg)

There will also be a community market happening the same day and the same time at the Ste. Genevieve Community Centre

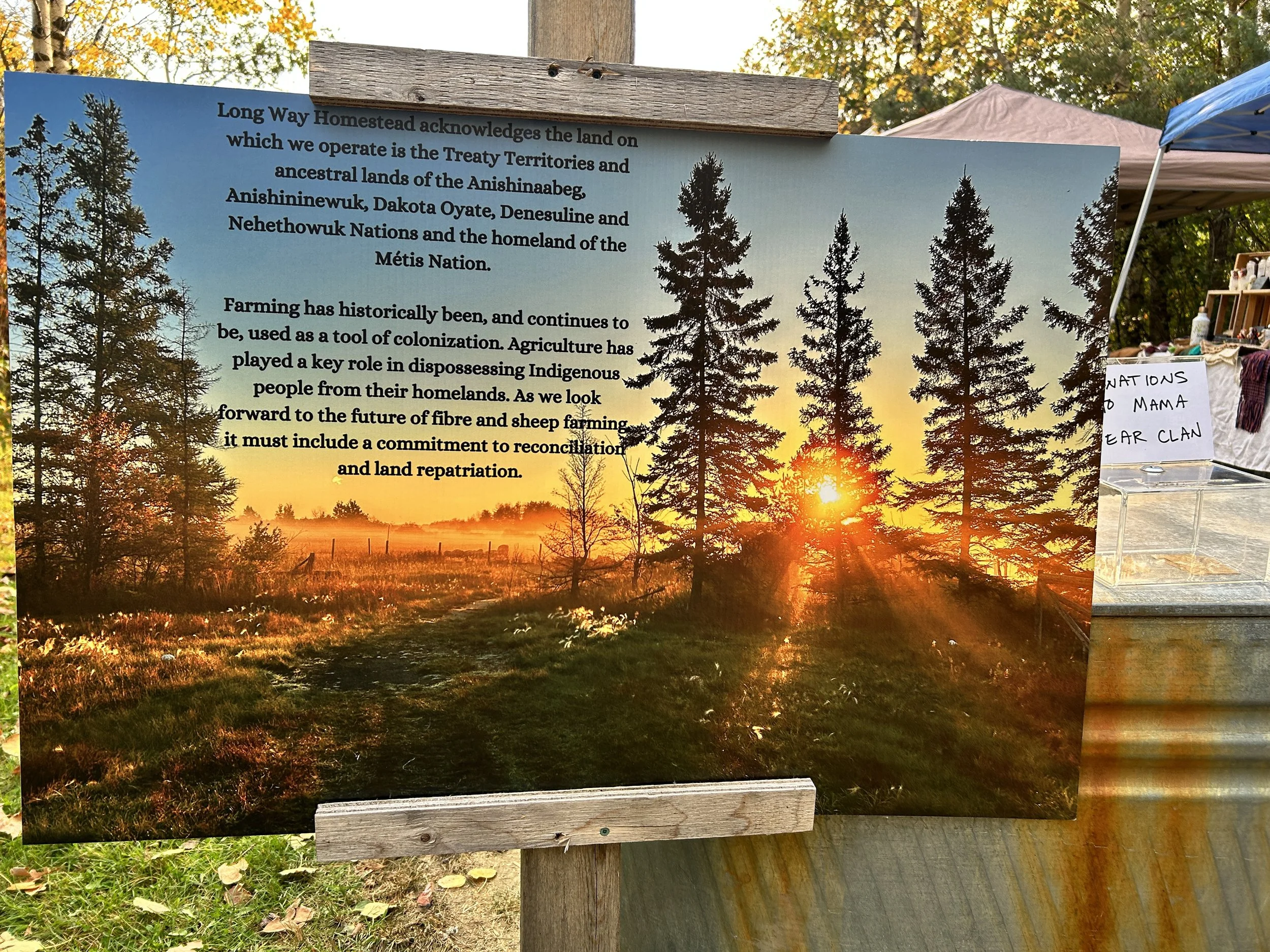

**The event is free, but we will have a donation box - all the funds will go to support Mama Bear Clan

There will be warm and cold beverages to purchase and pulled-lamb sandwiches at Long Way Homestead

Enjoy the cozy vibes of fall on the farm for the day. Bring your works-in-progress and sit by a fire, visit our sheep, tour the mill, hay rides and shop among local makers and farmers. Check out our list of Vendors!

Bear & Bunny Yarn

Apothecandy

Masagana Flower Farm

Enchanted Grove Alpacas

Swallowtail Farmstead

Sunflower Knit

The Tender

Awaken Herb Farm

Wild Woods Pottery

Between Two Farms

Masagana Flower Farm

Amanda Borealis

Accessibility: We are constantly working to make our facilities accessible. The driveway, walkways, dye studio and outdoor workshops spaces are grass and gravel and accessible by wheelchair. The outhouse, indoor studio space and wool mill all have one step access. We are working hard to improve accessibility on the farm, thank you for your patience.

Check out these images of past fibre and farm events!

Top 10 Take-Aways from Sheep & Wool Camp - by Jane Westheuser

Our inagural sheep & wool camp happened in June of 2024 and we are so honoured to have this recap and reflection from one of our participants of that very special week! (Thank you Jane)

It's September, and I've been catching up with friends who I haven't seen for a few months. Inevitably, someone asks, how was your summer? What did you get up to? And my response is always: I had a fantastic summer. And it all started with me going to Sheep and Wool Camp in Manitoba!

And then I wait for it. The awkward moment where my friend's inner voice is asking, what???? did she say Sheep and Wool Camp? And, every time, no matter who I'm chatting with, the next thing out of their mouth is - oh, so you learned to shear sheep, and did some sheep shearing?

So now I've prepared my "Top 10 Takeaways" and my answer isn't "no, I did not learn to shear sheep, I think you have to go to sheep shearing school for that!" but rather, "I learned so much, and let me tell you about some of it .

But first, a little context. I live in a city, on the west coast of Canada. I am an advanced beginner knitter and am still trying to understand the difference between DK, sport and worsted weight! I am a proud Canadian and like to support local. I am passionate about community and working together to make great things happen.

And that's why I registered for Sheep and Wool Camp: to learn from two Canadian shepherdesses (Anna and Christel) who are all about all of the above!

So, what did I learn at camp?

The term regenerative farming

Not sustainable farming - that means the land is in a steady, static state. Regenerative farming means the soil is restored, biodiversity grows, water and carbon are absorbed. That sure is good stuff for our planet! Anna and Christel told us: "We are not sheep farmers, we are grass farmers".

2. The grass is greener on the other side of the fence!

Long Way Homestead and Ferme Fiola use this nifty, easily movable temporary electro net fencing to create pasture for their flock (that's what the sheep herd is called). And we campers got to help move the fence. As soon as the sheep spotted us coming into their current pasture, they started bleating and nuzzling up to us, because they knew they were going to finally be able to graze on that grass that is on the other side of the fence!

We campers also got to sort out a fence that had been stored hastily and was all tangled up, just like yarn barf!

3. OK – just gonna say it - sheep are amazing, and adorable

Sheep produce meat, wool and milk! FYI - I knew that before camp. Most sheep farmers are raising sheep for meat. Wool from their sheep is a byproduct of the annual shearing. But there are more and more farmers raising sheep for their wool. I learned that the cheese from ewe milk (fromage de brébis – so delicious) industry is highly regulated in Canada.

Sheep are social. For obvious reasons, your ram is kept separate from your ewes. But you can't keep him on his own. You'll need another ram. He won't survive without the company!

Sheep don't like to let you know that they are sick. You really have to put your hands on your sheep regularly. Feel their spine, top of their tail, their ribs.

4. So many breeds of sheep

Samples of the breed wool - Sheep & Wool Camp 2024

I can't list them all here but from Romney to Clun Forest, from Shetland to Polypay, they are each unique in terms of wool – fine and long wools, down wool, dual coated wool. And each wool lends itself to a specific use – some better for felting, or for next to skin garments. There is colour variation in the wool from breed to breed.

Some breeds are better meat breeds. Some are rare breeds. Some are good for pasturing while others prefer to range. And, this I so love, the ewes of some breeds are really good mamas!

5. "What's with the llamas?"

When we "went out on the land" to walk among the sheep on day one of camp, there were a couple of llamas in both Anna and Christel's flocks. I finally asked the question. And was surprised by the answer. The llamas protect the flock. They are big and tall. And scare off predators like foxes. The llamas graze on the same land so you're not having to accommodate a special diet.

6. The bugs ARE big in Manitoba!

We arrived at camp after two weeks of non-stop, and heavy rain. Lots of swamp and puddles for mosquitoes to lay eggs, hatch and thrive. The bugs were awful. But no fear, Anna and Christel introduced us to wormwood (Artemisia absinthium) . This grass is a natural insect repellent that conveniently grows in the fields in Manitoba. Just pick a sprig or two and tuck it in your pocket and you're, more or less, bug free for a few hours.

7. Indigo go go!

I knew nothing about natural dying. Plants in various stages of growth and decay will result in pink, marigold, orange, fushcia, red. Indigo dye is the coolest. Anna grows indigo at Long Way Homestead. She made a vat of dye – a beautiful green colour. We chose our skeins of yarn (I chose three: a white, a light and a dark grey), put them carefully in the vat – you don't want to let oxygen into the dye. You wait. And then – you just as carefully pull out the skein. As it is exposed to oxygen …. it magically turns blue!

8. Fibreshed

Our shepherdesses, and a local alpaca farmer, kept talking about the Pembina Fibreshed. I finally asked what that was all about. They told me that a woman named Rebecca Burgess (American from California) was looking to understand how clothing can be locally grown, produced, designed and made. Kind of like the "100-mile diet", but for fibre. She came up with the term "fibreshed". After camp I did a bit more research and there are fibresheds everywhere! If you live in Canada, check out the Canadian Fibreshed Network to learn of your fibreshed, the members and their activities and advocacy work.

We campers toured the mill at Long Way Homestead – it was more like pivoting on the spot – to see raw fleece cleaned, dried, picked, carded, drawn, spun, plied, steamed and wound onto cones. And who knew, this mini mill was manufactured right here in Canada, in PEI! Belfast Mini Mills is recognized around the world for its small mills that can fit inside a standard garage.

10. It's tough for Canadian wool growers – but it's getting better!

The shepherdesses shared some sobering numbers about sheep farmers and how little money they make for their fleeces. Most raise sheep for meat. But they do need to shear their animals every year. And that's means there is a lot of wool produced. For these sheep farmers, it is not worth it for them to sell the fleeces, and they often end up throwing out their annual "clip" – wool that is perfect for clothing, bedding or insulation.

And if you're a farmer who is raising sheep for wool? Where can you go to get a decent price for your fleece? How can you make a living?

Well, the good news is, things are changing. Thanks to people like Anna and Christel, and things like Sheep and Wool Camp, folk are becoming more aware of how important it is to buy local and are searching out their local fibre producers. And now there is this: Canadian Wool Certification – a logo wool producers can put on their products so we know the wool was grown and manufactured in Canada.

I hope my ramblings have made you curious, inspired you or at least amused you.

Do you want to go to Sheep and Wool Camp next year? I sure want to go back! Hope to see you there!

Jane